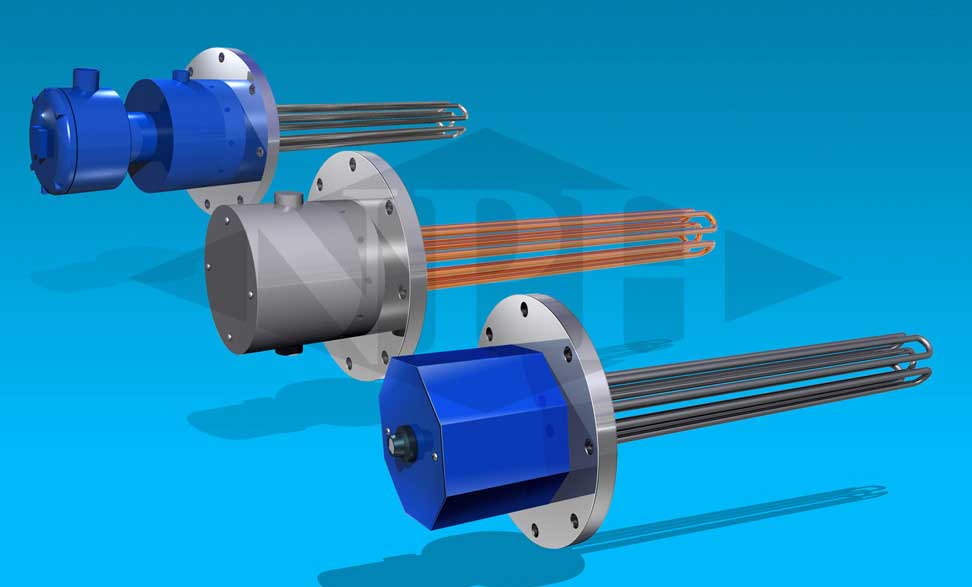

Flange Immersion Heaters & CSA Listed Explosion Proof/Hazardous Area, Nema 7 Flanged Immersion Heaters-For Industrial Applications

Hazardous Area/Explosion Proof Flanged Heaters & Custom

Flanged Immersion Heaters

Hazardous Area/Explosion Proof Flanged Heaters & Custom

Flanged Immersion Heaters  Standard and Custom Flanged Immersion Heaters-Construction

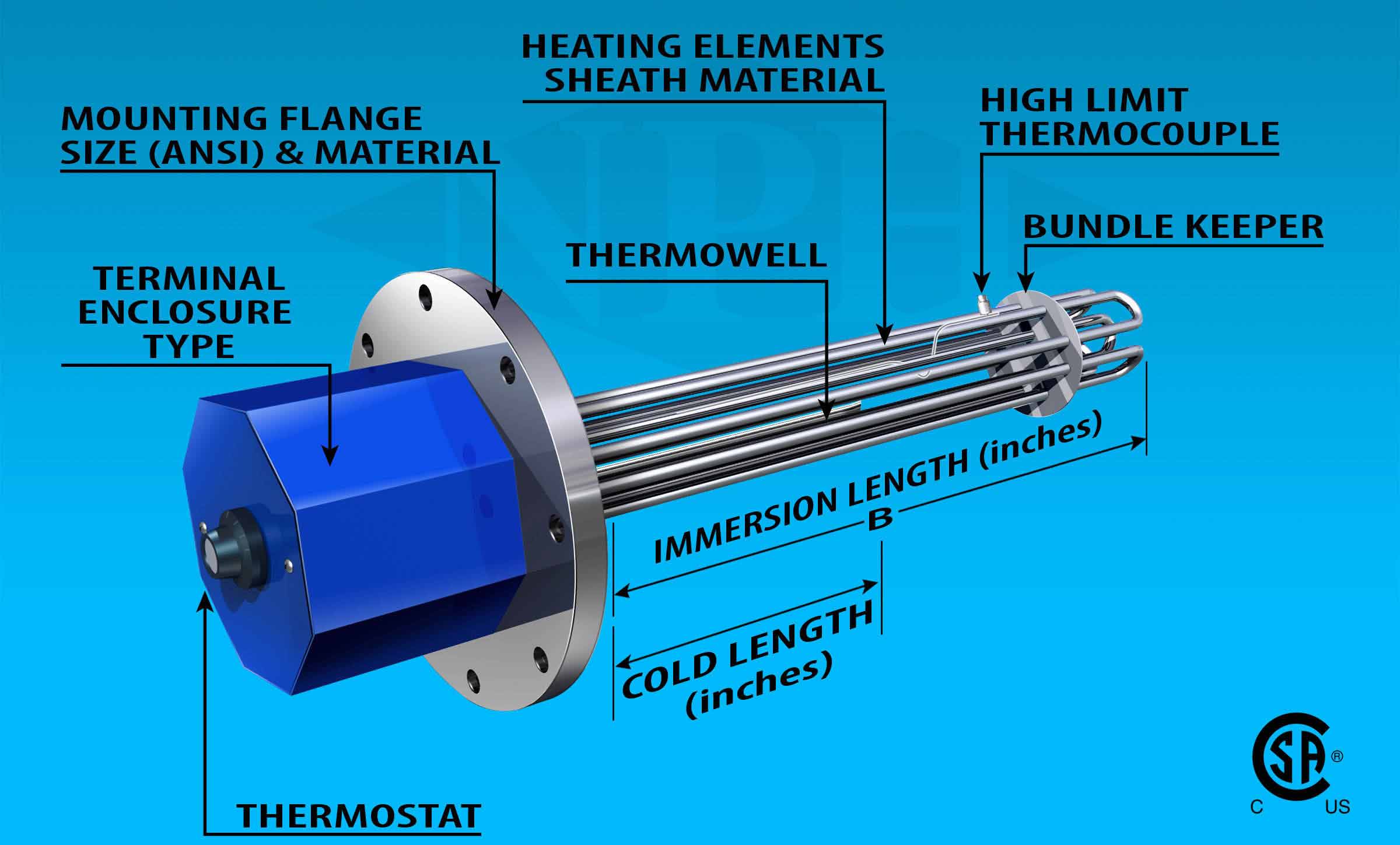

Components

Standard and Custom Flanged Immersion Heaters-Construction

Components Flanged Immersion Heaters (Custom Flanges) - Description Review:

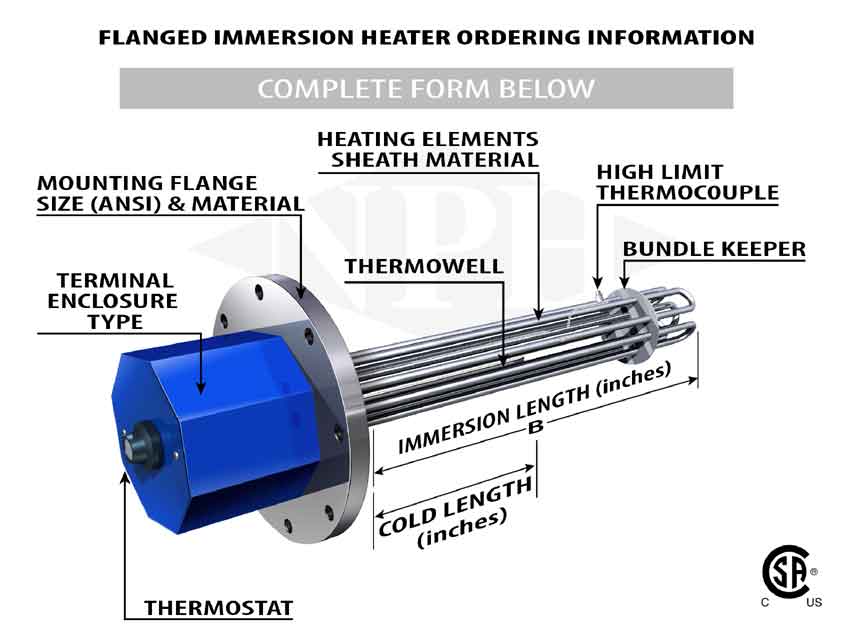

ANSI round flange and non ANSI square flange models in reference to flanged immersion heaters are often the right choice for most applications requiring higher wattages like the heating of water, oil and rinsing tanks. These custom flanged Immersion heaters are designed to install into a pipe body, pressure vessel or a tank using any standard pipe size. Most custom fabricated flanged immersion heaters are available in various flange sizes and sheath materials suitable for the heating requirements of water, air, gas and other liquids/substances. Also available with a wide selection of pressure rates/ranges and for hazardous or explosion proof environments. If you are looking for efficient heaters then go with flanged immersion heaters since all energy generated is transferred directly into the heated medium.

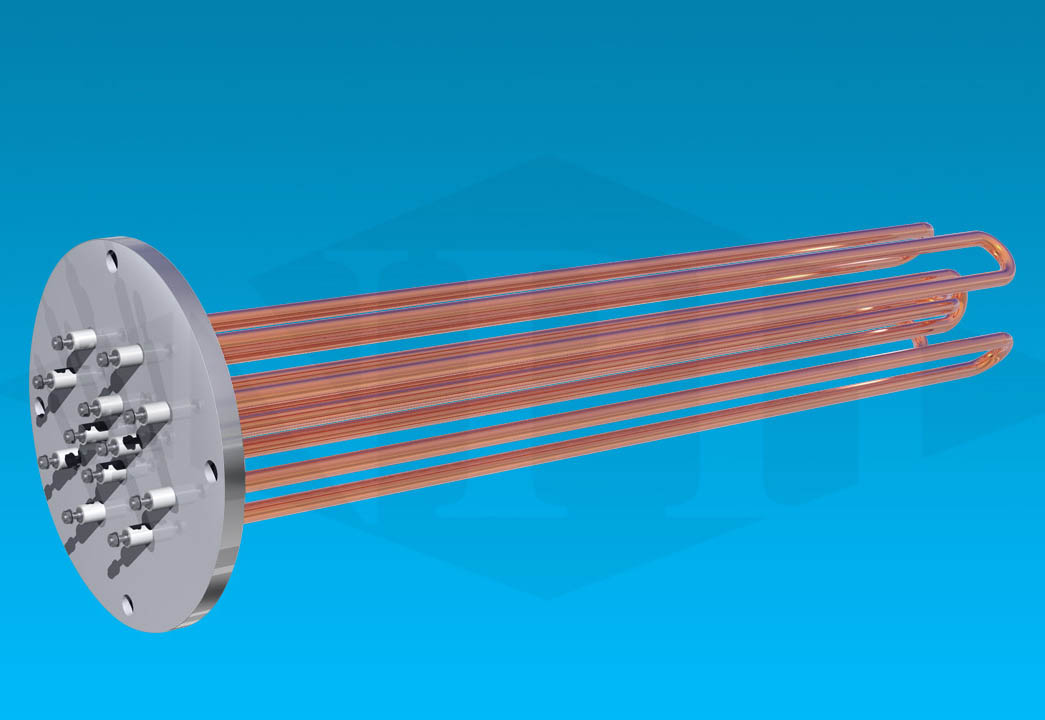

Construction of custom fabricated flange/flanged immersion heaters incorporates tubular heater design which are either welded or brazed into a ANSI carbon steel pipe flange. General purpose (NEMA 1) termina/electricall enclosures come with all standard units. Also available in moisture resistant (NEMA 4) and explosion proof/hazardous area (NEMA 7) models. Titanium, Incoloy, Stainless Steel, Steel, and Copper sheath materials can be used as required for all custom and customer specific applications.

The most common or standard flanged immersion heaters come with 150 lbs flanges, however, other flange pressure ratings like 300 lbs and 600 lbs flanges are also available. To determine applicable watt density and proper sheath materials to be chosen for your application consult NPH. Our flanged and hazardous area/explosion proof immersion heaters are CSA/NRTL and UL recognized

Construction-Custom Flanged Immersion Heaters:

Custom Flanged Immersion Heaters: Specifications, Installation, Maintenance and Operation Guide, Technical Letters & Tips:

- Hot Water Storage Tanks

- CSA Listed Explosion Proof/Hazardous Area Heaters

- All Oil Grades

- Equipment for Food Processing

- Heat Transfer Systems

- Cleaning/Rinsing Tanks

- Equipment for Process Air

- Boiler Equipment

- Freeze Protection of Fluids

- Application for Petro Chemical

- Oil Heating Loops

- Water/Recycling and Sewage Processing Application

- Purification & Caustic Solutions

Standard Flanged Immersion Heaters-Construction Features:

Elements Materials- Copper, Steel, 304/316 Stainless Steel, Incoloy

Number of Elements in Flanges- 3, 6, 9, 12, 18, 21, 27, 36, 45 plus

Element Diameter- 0.315" – 0.430"

Watt Density- 6.5, 15, 23, 45, 75W/in2

Flange - Materials- Carbon Steel, Stainless Steel,

Flange Rating- 150 lb. Pressure Class per ANSI B16.5

Flange Sizes- 3", 5", 6", 8" 10", 12", 14", 150 lb.

Our Flanged Immersion Heaters offer Highly Conductive Tubular Heating Elements- NPHcustom flanged immersion heaterelements use the purest blends of magnesium oxide (MgO) powder. In addition this refractory is compacted to a rock hard like density. This is important because it ensures (i) maximum thermal conduction and (ii) maximum electrical resistance, promoting long coil/resistance wire life.

NPH Flanged Immersion Heaters offer Heavy Coil Construction- Heating coils are designed for low watt density operation. This is accomplished by increasing the coil diameter and length and thereby increasing the surface area of the coil, limiting the surface temperature of the resitance wire yielding longer coil and therfore heater life.

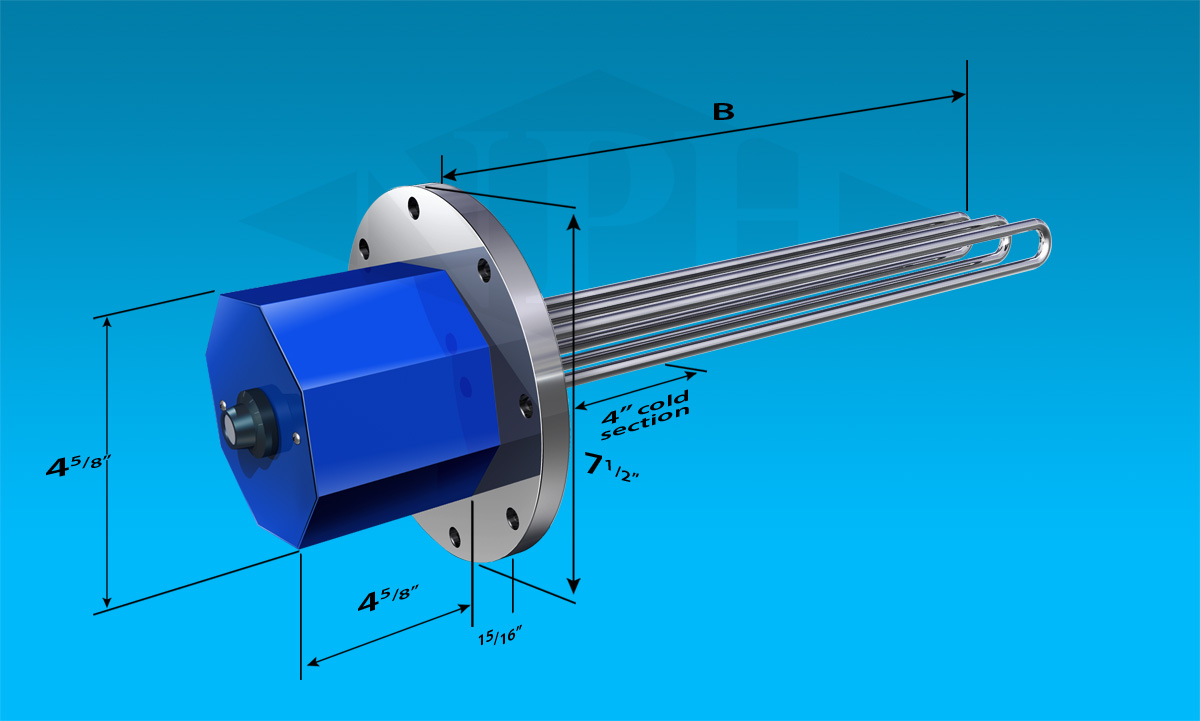

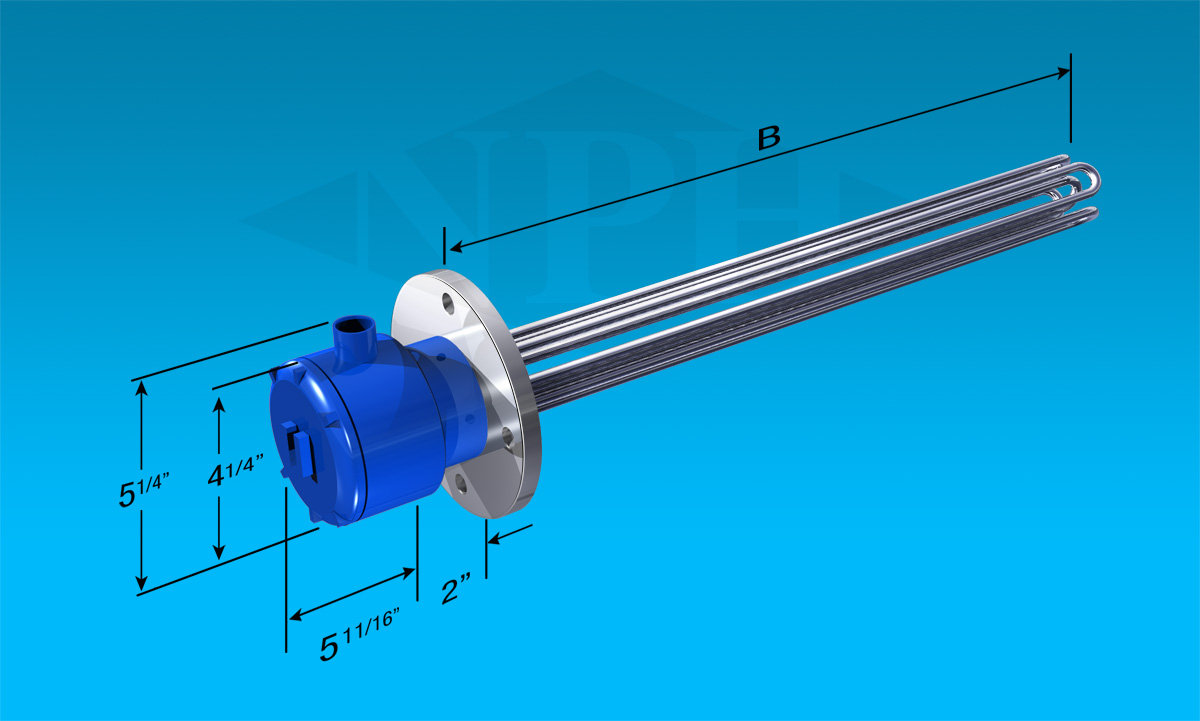

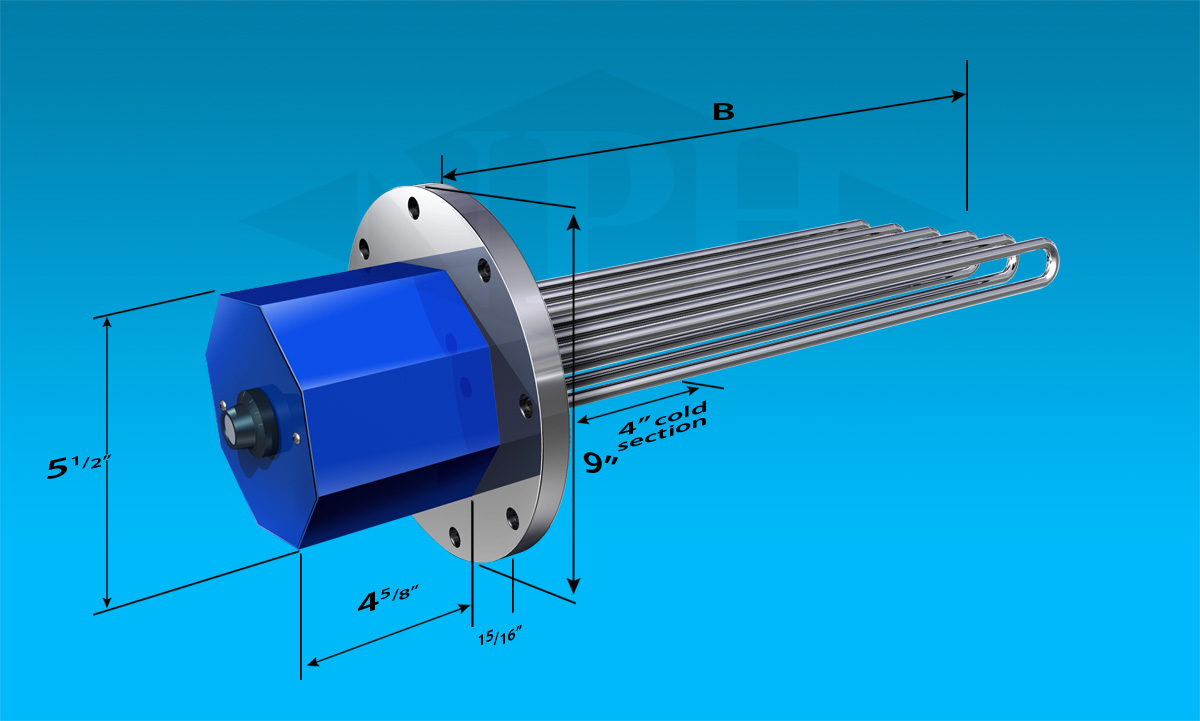

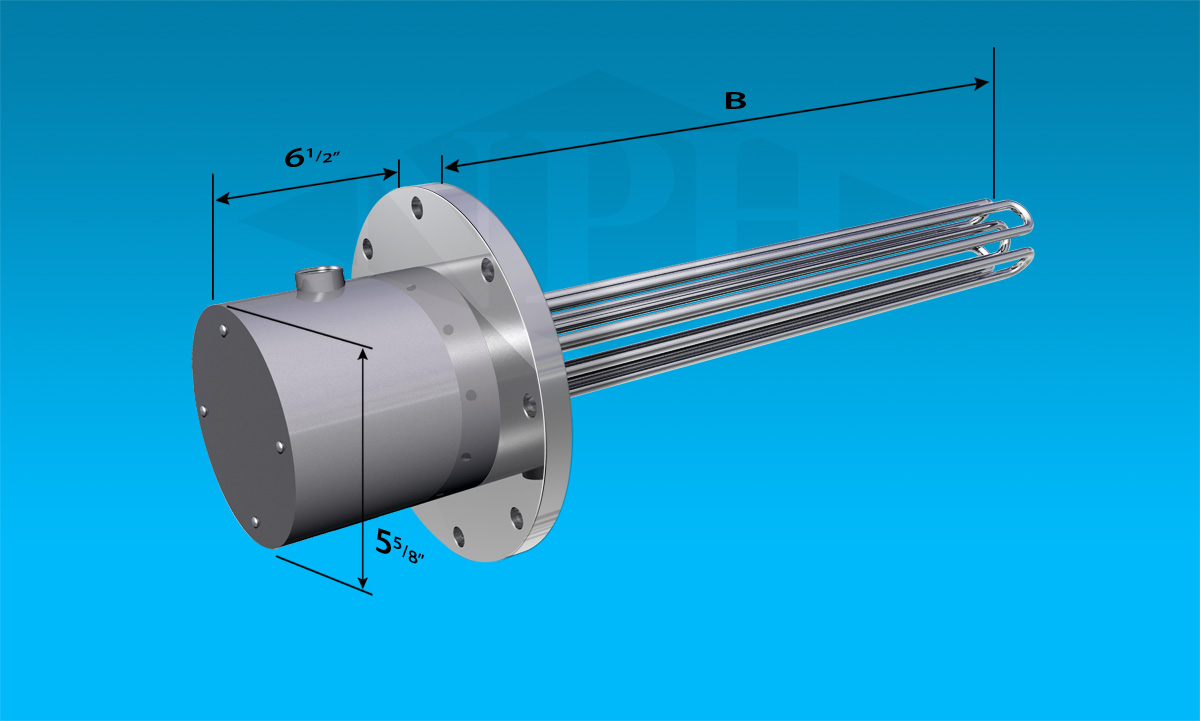

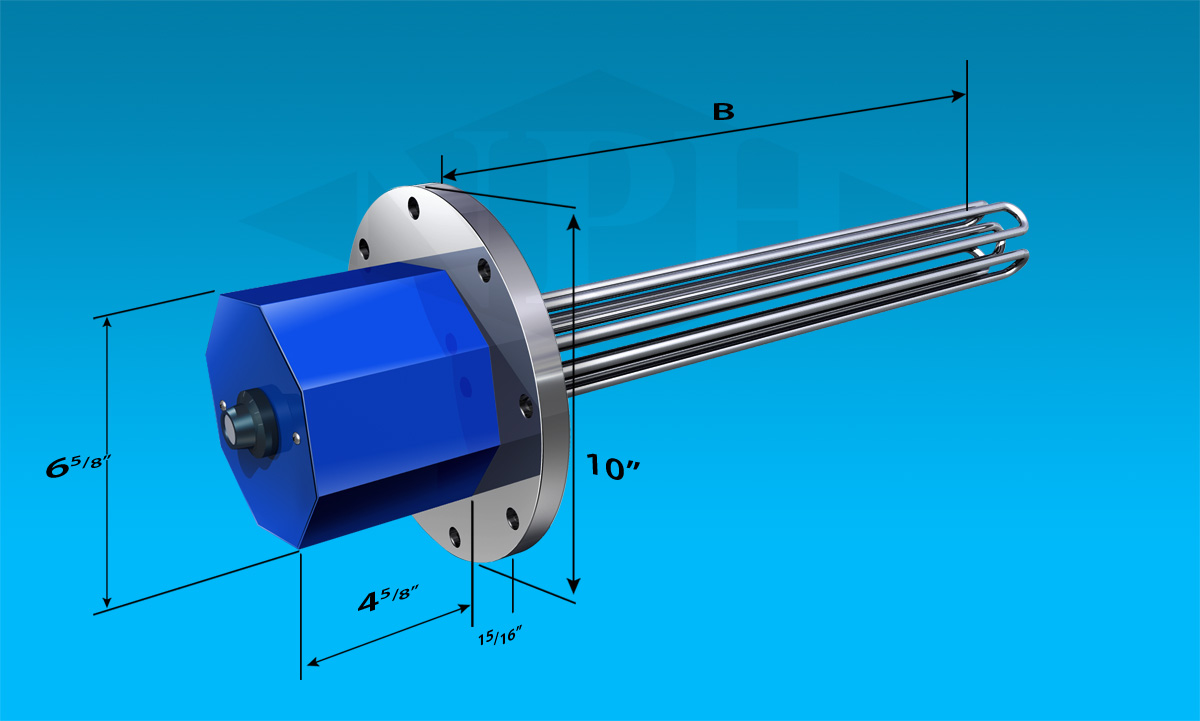

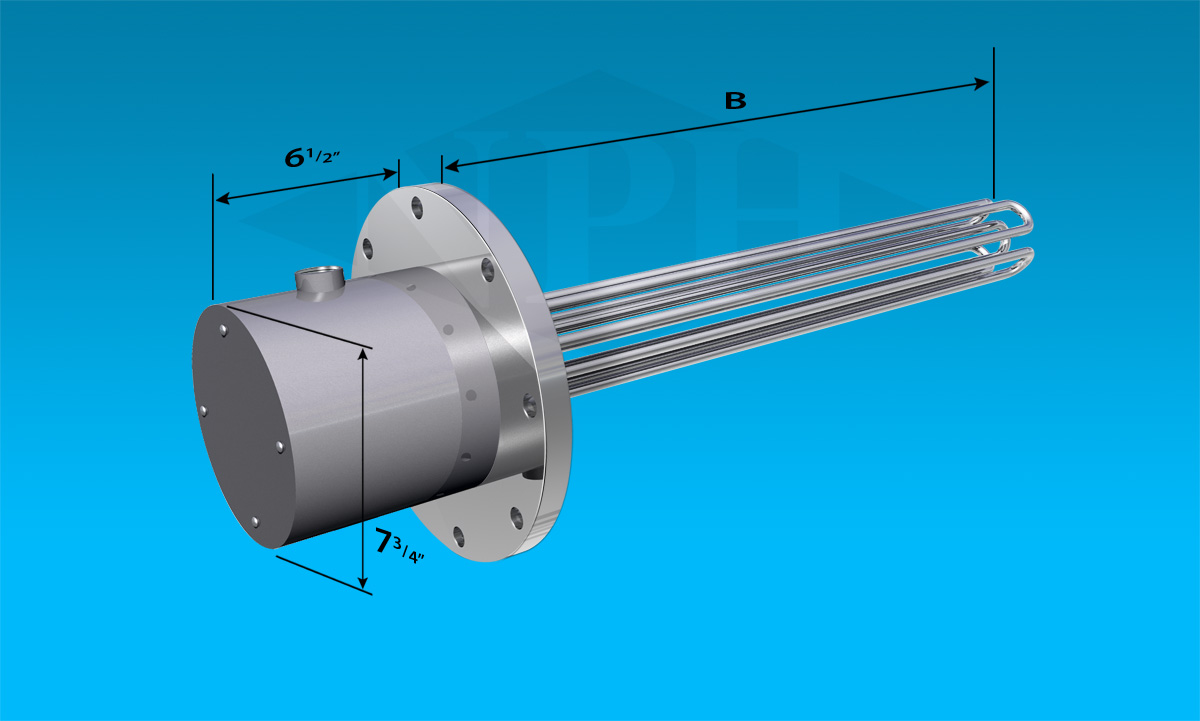

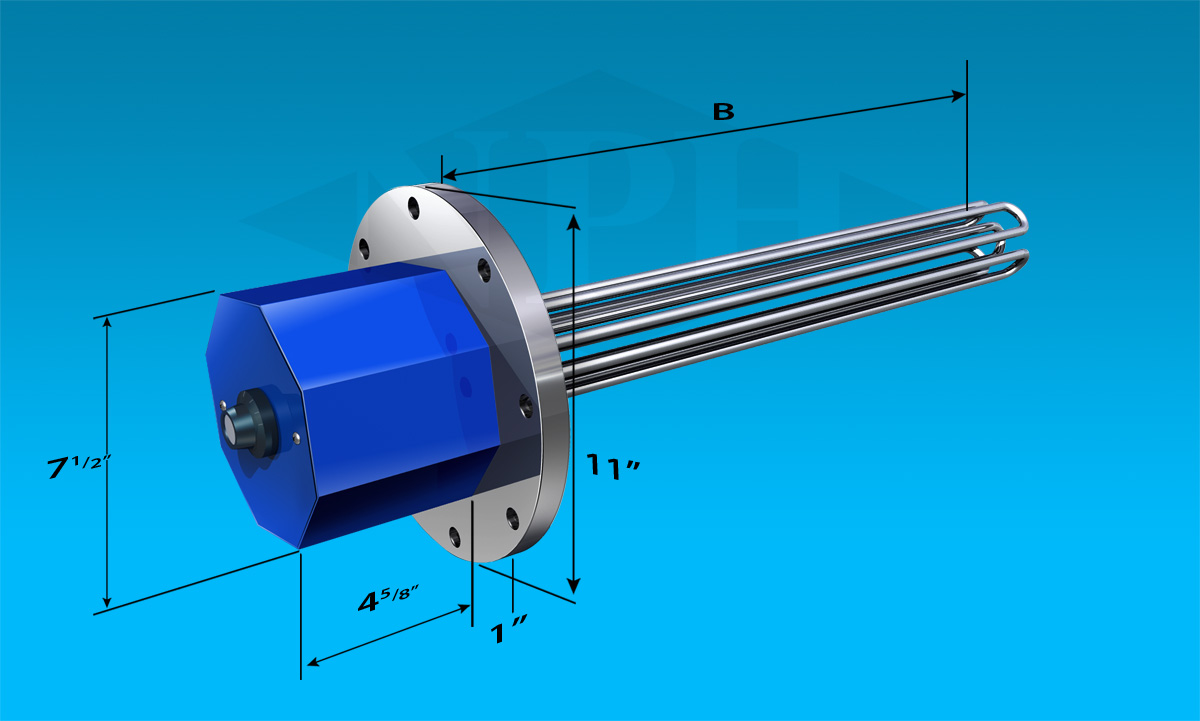

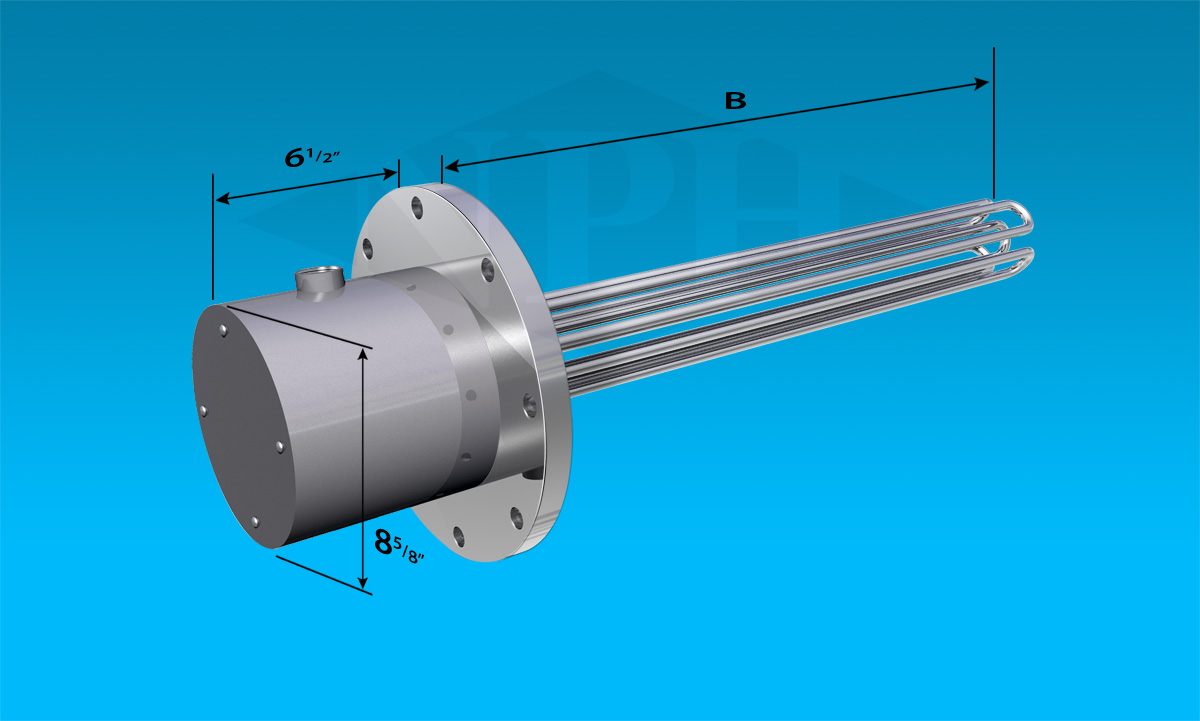

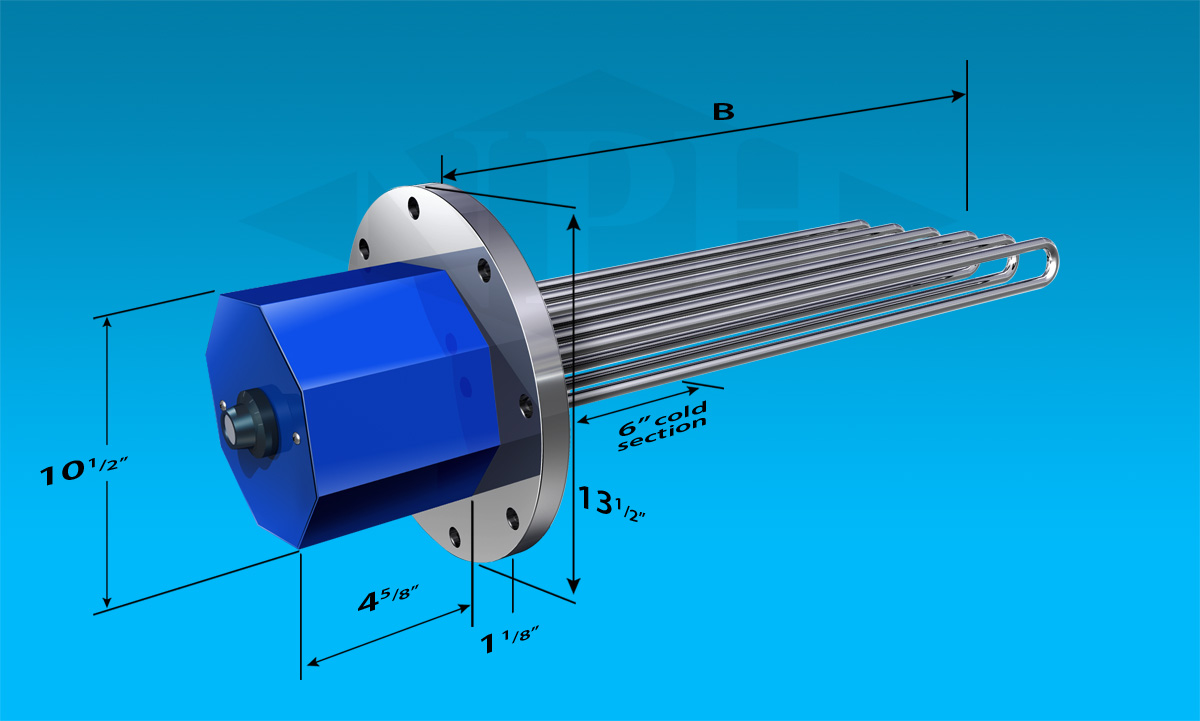

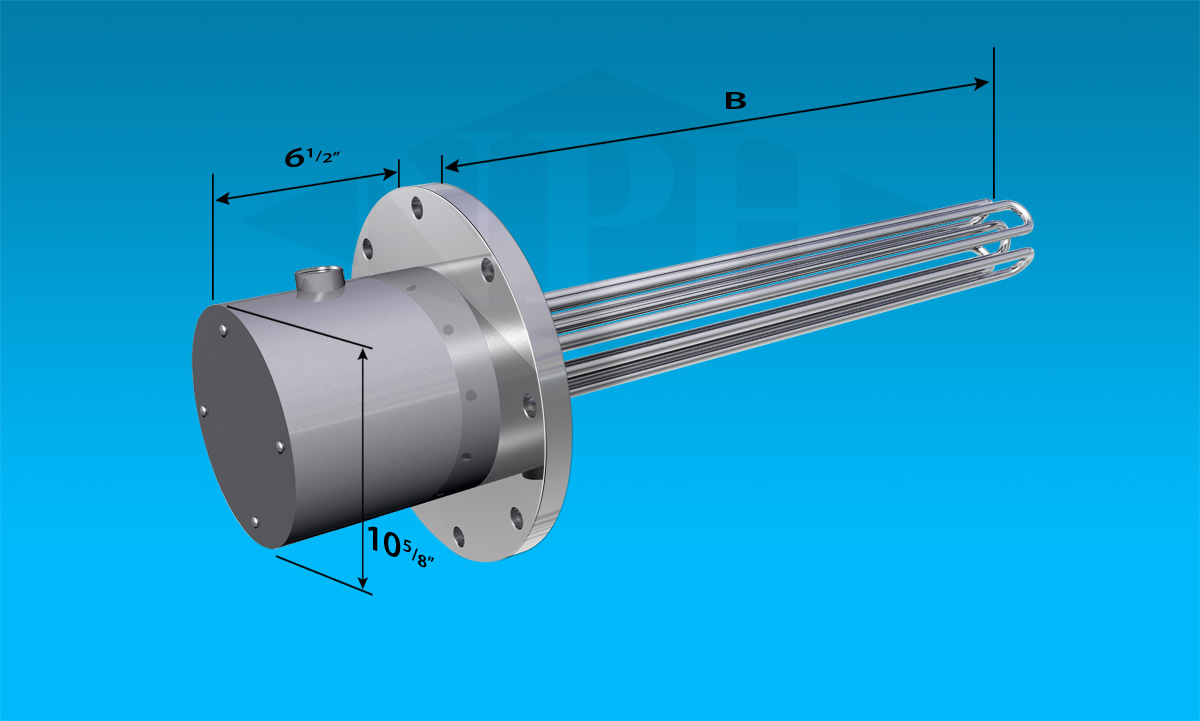

Common Industrial Process Heater Terminal Enclosure Types - See Images Below:

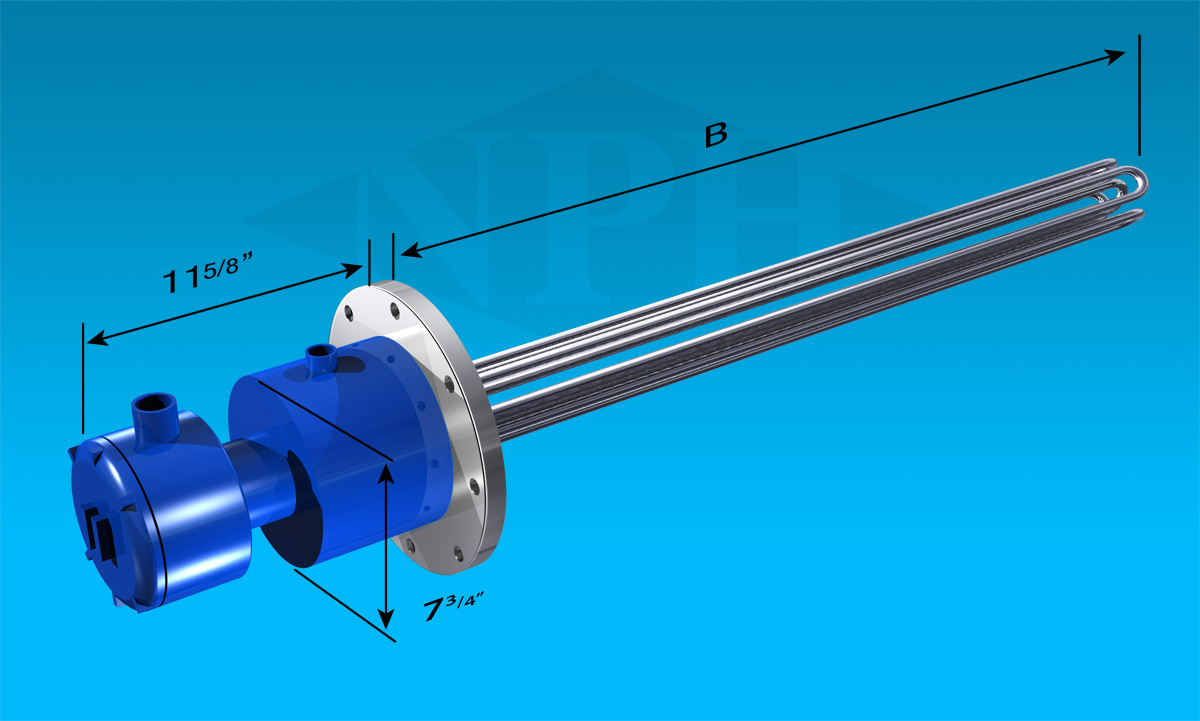

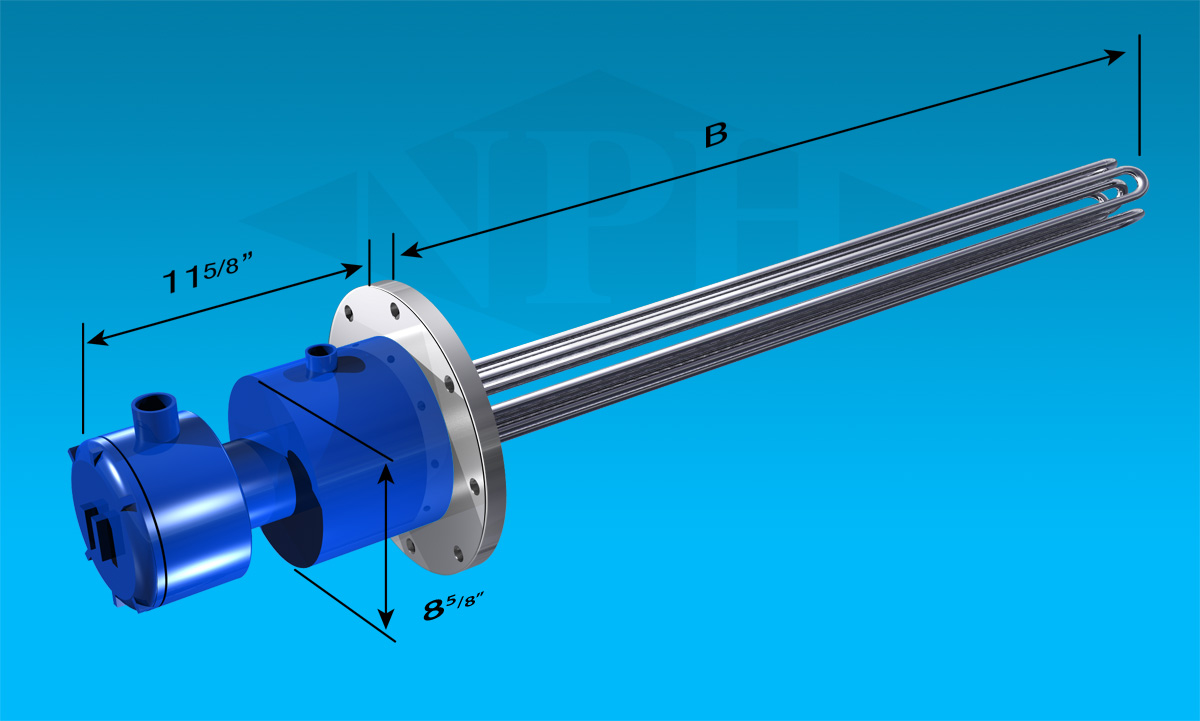

NEMA 1 -3"-150 LB ANSI Flanged Heater, General Purpose Enclosure

NEMA 4 -3"-150 LB ANSI Flanged Heater, Moisture Resistant Enclosure

NEMA 1 -4"-150 LB ANSI Flanged Heater, General Purpose Enclosure

NEMA 4 -4"-150 LB ANSI Flanged Heater, Moisture Resistant Enclosure

NEMA 1 -5"-150 LB ANSI Flanged Heater, General Purpose Enclosure

NEMA 4 -5"-150 LB ANSI Flanged Heater, Moisture Resistant

NEMA 1 -6"-150 LB ANSI Flanged Heater, General Purpose Enclosure

NEMA 4 -6"-150 LB ANSI Flanged Heater, Moisture Resistant

NEMA 1 -8"-150 LB ANSI Flanged Heater, General Purpose Enclosure

NEMA 4 -8"-150 LB ANSI Flanged Heater, Moisture Resistant

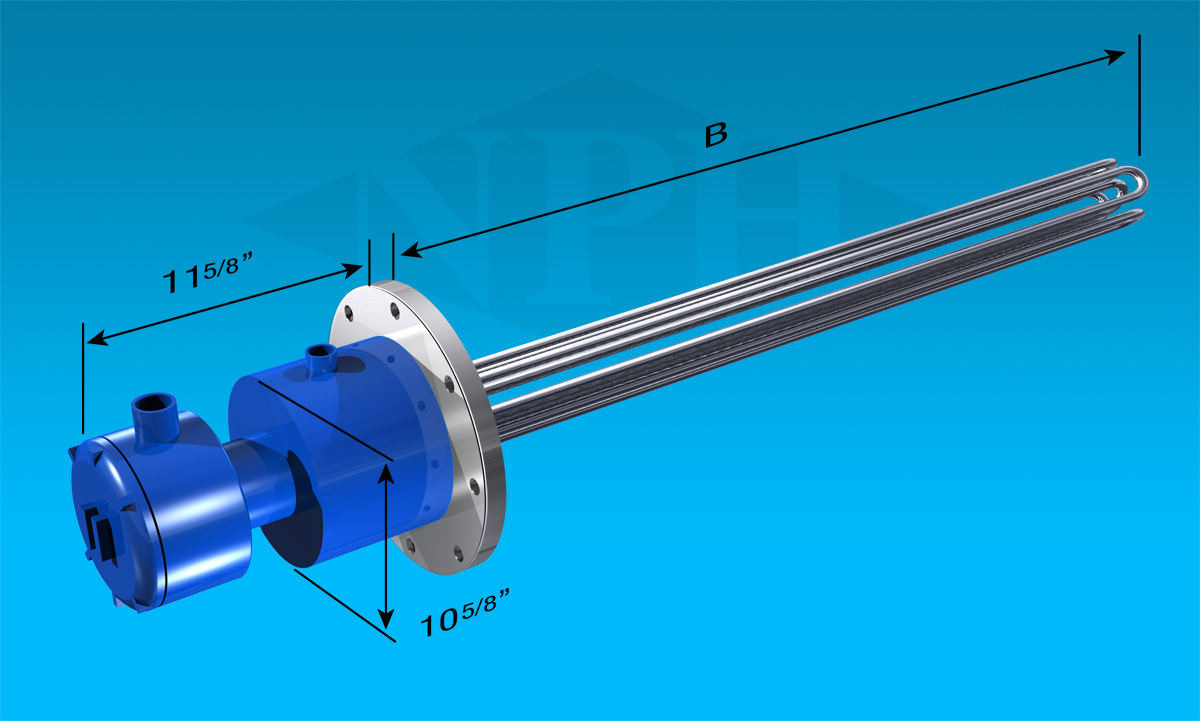

NEMA 7 -5"-150 LB ANSI Flanged Heater, Hazardous Location Enclosure

NEMA 7 -6"-150 LB ANSI Flanged Heater, Hazardous Location

NEMA 7 -8"-150 LB ANSI Flanged Heater, Hazardous Location

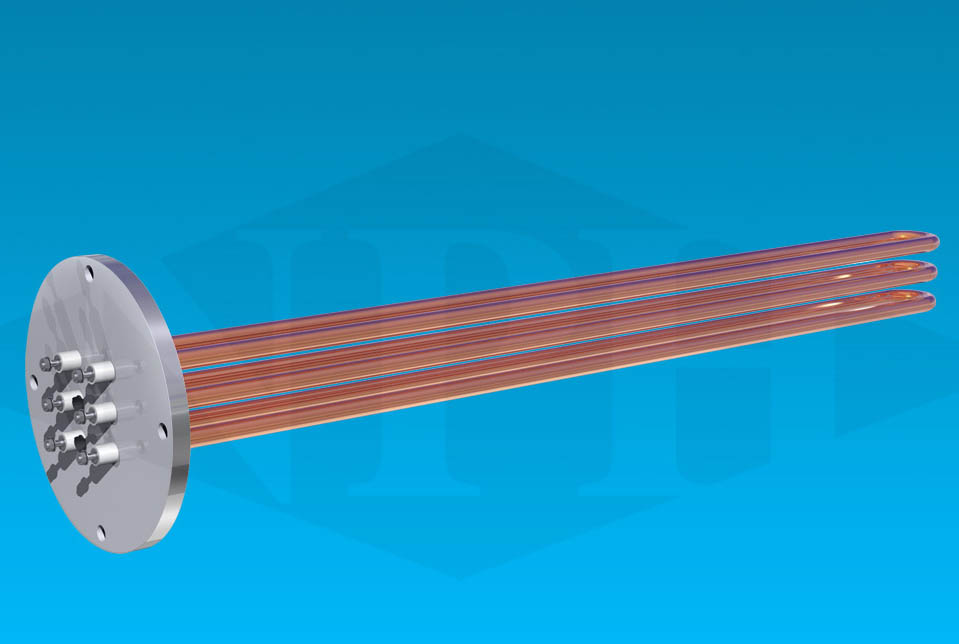

Non Ansi Flanges-Boiler and Thermolator Immersion -Round Flange-Available in Various Diameters-6 Elements

Non Ansi Flanges-Boiler and Thermolator Immersion -Round Flange-Available in Various Diameters-3 Elements

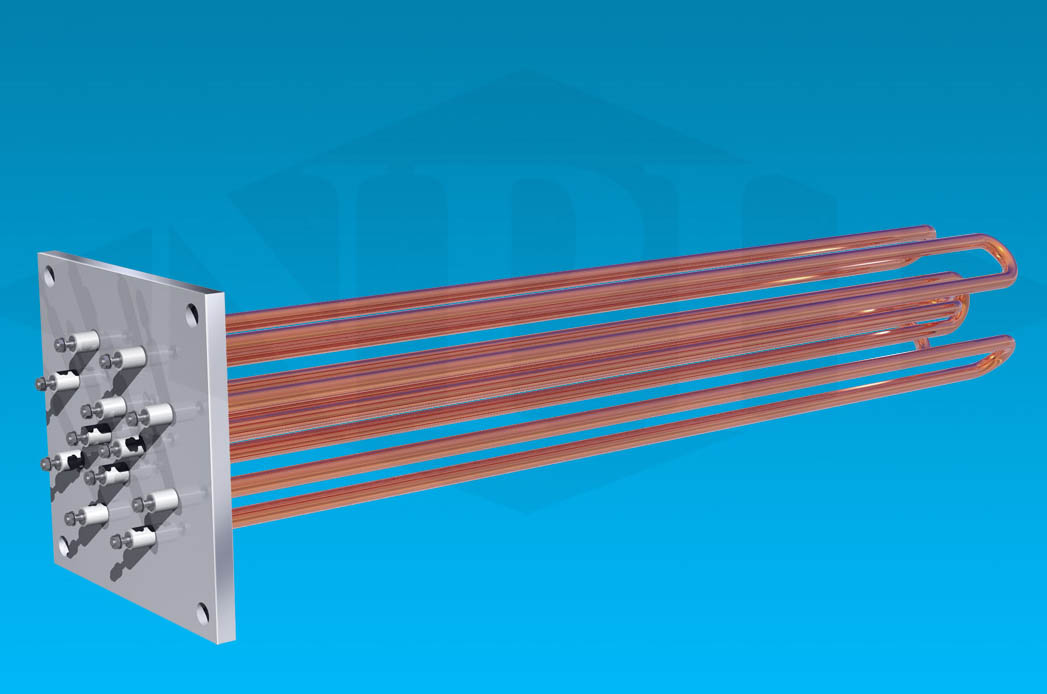

Non Ansi Flanges-Boiler and Thermolator Immersion -Square Flange-Available in Various Diameters-6 Elements

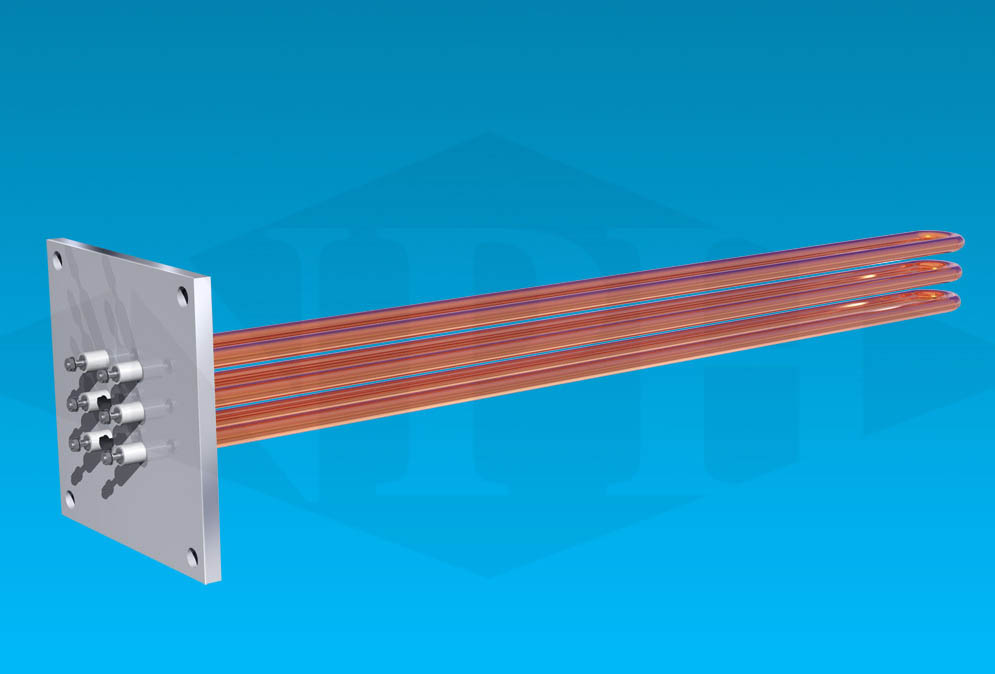

Non Ansi Flanges-Boiler and Thermolator Immersion -Square Flange-Available in Various Diameters-3 Elements

Safe operation of heaters (including explosion proof/hazardous areas) equipped with these enclosures depends on employment of electrical wiring meeting National Electric Code and limiting maximum operating temperatures (including temperatures on outside of vessel, piping, flanges, screw-plugs, enclosures and other heat conducting parts) as dictated by flammable liquids, vapors, or gases present. Approved pressure and/or temperature limiting controls must be used to assure safe operation in the event of system malfunction. Common Flanged Immersion Heaters-Nema Enclosure Types–See Below:

- NEMA 1- General purpose, sheet metal, painted with enamel.

- NEMA 4- Moisture Resistant. These enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and windblown dust); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (rain, sleet, snow, splashing water, and hose directed water); and that will be undamaged by the external formation of ice on the enclosure.

- NEMA 4X- Enclosures are primarily intended for indoor/outdoor use and offer a superior level of protection from corrosion and extreme environments. Provide a degree of protection against windblown dust and rain, splashing water, hose directed water, and damage from external ice formation.

- NEMA 7- Explosion Proof Enclosures are designed to contain an internal explosion without causing an external hazard. These enclosures are intended for indoor use in hazardous locations classified as Class I, Division I, Groups A,B,C, or D.

Grounding Connector Standard - A solid terminal connector is standard on all NPH immersion heaters insuring positive ground and personal safety. Special Flanged Immersion Heaters-Features Available:

Kilowatt Ratings - 500 KW and above available

Flanges:

Materials- 316, 321, 347 stainless steel. Inconel, Incoloy

Ratings- 300 lb. up to 2500 lb., pressure classes available

Sizes- 10" , 12", 14", 16", and 18" available. Please contact NPH for other materials or ratings.

Elements Materials- 316, 321, 347 stainless steel. Inconel. Other materials available, please contact NPH

Other Features- ASME Sections I, IV, and VIII designed and certified. Baffles on elements to distribute flow. Passivation on stainless steel. Immersion lengths up to 240". Underwriters Laboratories U.L./CSA listing available. Consult NPH.

National Plastic Heater Corrosion Policy:

NPH does not warrant any of its flanged immersion heaters against damage from corrosion, contamination, misapplication, improper specification or operating conditions beyond our control. NPH will suggest/recommend sheath materials and watt densities from time to time however, it is the responsibility of the purchaser and his engineer to make the ultimate choice of sheath material based on his knowledge of chemical composition of corrosive solution, character of materials entering the solution, and controls which he maintains on the process. Further, since NPH has no control over the use and sometimes misuse of the heaters, we cannot guarantee against burnouts.

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide