NATIONAL PLASTIC HEATER, SENSOR & CONTROL INC. Industrial Process Heating, Temperature Sensing & Control Technology For Industry |

| Toll Free: 1-877-674-9744 | ||

| Visit Our Online Store To Purchase Our High Temperature European Connectors, High Temperature Accessories and Miniature Cartridge Heaters | ||

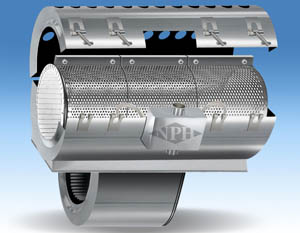

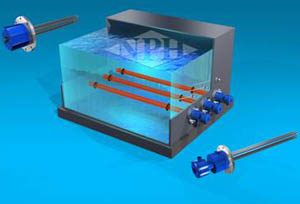

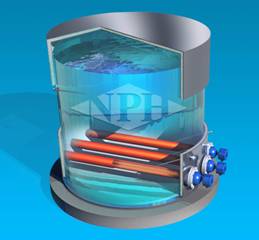

Industrial Oven Solutions Offering Custom Energy Efficient Medium Wave Quartz Infrared Ovens For The Thermoforming, Packaging And As Heaters For Paint Curing, Printing And Drying. National Plastic Heater Specializes In The Engineering And Supply Of Ovens, Control Solutions And Components For A Vast Array Of Other Industries As Well.

Quartz Infrared Ovens and Panels

Quartz Infrared Ovens and Custom Panels

Custom Quartz Ovens and Panels

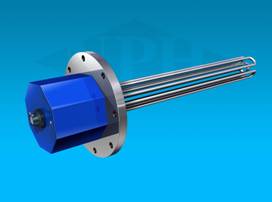

Medium wave electric infrared heating elements employ a NiCr wire element inside a quartz tube to transfer heat to the part. This heating element is sometimes referred to as a medium wave quartz tube element. This heating technique has several features and related benefits:

Medium Wave Quartz Infrared Ovens:

X" x Y" heated area

X" x Y" heated area

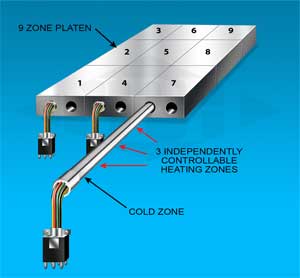

X heaters per zone for X zones of control, customer specific

X heaters per zone for X zones of control, customer specific

"Intelligent Infrared" uses highly efficient elements and unlimited zone control options

"Intelligent Infrared" uses highly efficient elements and unlimited zone control options

- High Heating Rates: The source temperature (up to 2,000 Deg F) of the NiCr element produces a wavelength of approximately 2.5 micron leading to high thermal transfer and fast heating. This medium wavelength is especially efficient for drying processes.

- Fast Response: The low thermal mass of the NiCr element gives very good control of the heat output and process temperature.

- Controllable Output: Output of our medium wave electric infrared oven and furnace systems can be controlled precisely to match the temperature requirements of the process.

- Clean Heating: The medium wave electric heat source is environmentally clean and efficient.

- High Heating Efficiencies: Up to 60% of input electrical power is converted to medium wave radiant energy (heat). Medium elements are particularly suited for drying applications due to the match of the emitted wavelength of the element with the absorption peak of water.

The choice of short wave or medium wave technology depends upon a number of factors related to the process and customer requirements. NPH engineer's shall specify the element which is best suited to your specific application.

Medium Wave Quartz Infrared Ovens:

in order to minimize energy, maximize production, and reduce scrap