NATIONAL PLASTIC HEATER, SENSOR & CONTROL INC. Industrial Process Heating, Temperature Sensing & Control Technology For Industry |

| Toll Free: 1-877-674-9744 | ||

| Visit Our Online Store To Purchase Our High Temperature European Connectors, High Temperature Accessories and Miniature Cartridge Heaters | ||

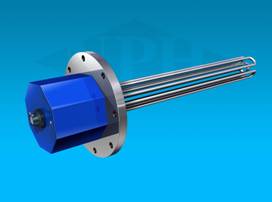

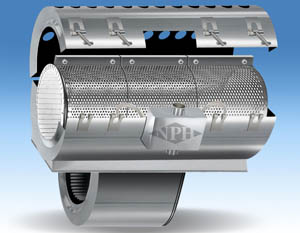

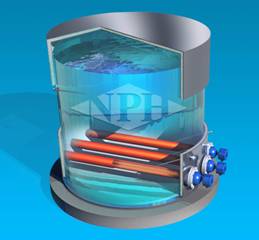

Explosion Proof Drum Heaters | Explosion Resistant Drum Heaters

2.jpg) -3.jpg) |

Hazardous Area Explosion Proof Drum Heaters with Explosion Proof Temperature Controller

Hazardous Area Explosion Proof Drum Heaters - Product Description

Serious quality FM approved Hazardous Area Explosion Proof Drum Heaters are low-watt density electric mat heaters with explosion resistant temperature controllers for T3 and T4A environments. Providing an efficient means of freeze protection, viscosity control and melting of solids in Class I, Division 2 areas . Hazardous environments have special considerations in order to keep it safe such as auto-ignition points. No matter what needs to be heated, we have a solution that meets the rigorous criteria of a hazardous area.

- Exclusive hazardous-area approval

- Class I Division 2 Groups A*, B, C, and D Class II Division 2 Groups F and G

- Dual set-point NEMA 7 temperature controller connected to a high temperature limit indicator light

- Exceptional 8" (203mm) coverage area

- Superior durability and flexibility

- Moisture and chemical resistant

- Patented grounded heating element meets NEC 427.23

* only for drum heater without NEMA 7 temperature controller. Contact factory for more information.

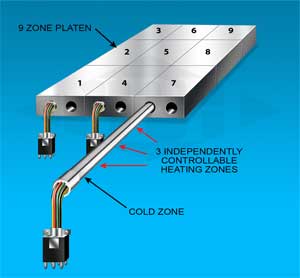

Specifications-Hazardous Area Explosion Proof Drum Heaters:

- 8" (203mm) wide band

- High-limit thermostat designed to keep heater below NEC article 500 T-rating

- Power density: 2.5 watts/in2 (.004 watts/mm2)

- Heating element is laminated between two layers of 23mil and two layers of 25mil fiberglass reinforced silicone rubber

- Nominal silicone rubber density of 26 oz/yd2 (881 grams/m2) per layer

- Attached adjustable dual set-point NEMA 7 temperature controller with power cord 6 feet (1.8) long. One set-point is set at a high temperature limit and connected to read indicator light.

- Blanket leads 6 feet (1.8m)long for NEMA 7 controller; 1 foot (0.3M) without controller

- Leads from blanket to controller are enclosed in a liquid tight conduit

- 392oF (200oC) maximum exposure temperature on heating surface

- Hazardous Area Drum Heaters-Designed for use on metal drums

| T Rating | NEC Temperature | Actual High Limit Thermostat |

| T3 | 392oF (200oC) | 292oF (145oC) |

| T4A | 248oF (120oC) | 158oF (70oC) |

|

Gallon

(Liter) Size

|

Diameter in

(mm)

|

Total

Wattage

|

Length in

(mm)

|

Width in

(mm)

|

Part Number

120VAC 240VAC

|

| 30 (114) | 18.6 (473) | 1000 | 58.5 (1496) | 8 (203) | DHCX231000T3 DHCX231000T3 |

| 55 (208) | 22.3 (565) | 1300 | 70.0 (1778) | 8 (203) | DHCX151300T3 DHCX251300T3 |

For T4A rated environments

|

Gallon

(Liter) Size

|

Diameter in

(mm)

|

Total

Wattage

|

Length in

(mm)

|

Width in

(mm)

|

Part Number

120VAC 240VAC

|

| 30 (114) | 18.6 (473) | 1000 |

58.5

(1496)

|

8 (203) | DHCX131000T4A DHCX231000T4A |

| 55 (208) | 22.3 (565) | 1300 |

70.0

(1778)

|

8 (203) | DHCX151300T4A DHCX251300T4A |

- Gas Plants

- Spray Booths

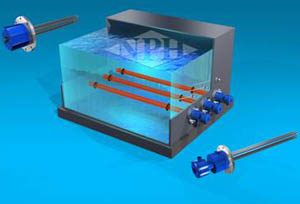

- Heating & Preheating

- All Grades of Oil

- Heat Transfer Systems

- Pulp and Paper Mills

- Other Applications Requiring Heat for Hazardous Materials

Hazardous Area Explosion Proof Silicone Rubber Drum and Pail Heaters: Specifications, Manuals, Technical Letters & Tips:

| |

Hazardous Area Explosion Proof Silicone Rubber Drum and Pail |

| |

|

| |

Click to open request for quote form

2) Specify Watts and Volts

3) Specify T Rating - T3 or T4A. See Chart above for ratings

4) Specify part number from charts above

5) Provide specific heat of material being heated

6) Specify material being heated

7) Specify number of units required

8) Specify type of application and its parameters

How To Order Explosion Proof Hazardous Area Drum Heaters

1) Specify 30 or 55 Gallon Explosion Proof Hazardous Area Drum Heater2) Specify Watts and Volts

3) Specify T Rating - T3 or T4A. See Chart above for ratings

4) Specify part number from charts above

5) Provide specific heat of material being heated

6) Specify material being heated

7) Specify number of units required

8) Specify type of application and its parameters