Best Cartridge Heaters-maintenance and heater failure prevention tips

Review Cartridge Heaters Custom Guide: What are cartridge heaters, pencil heaters, rod heaters or insertion heaters?

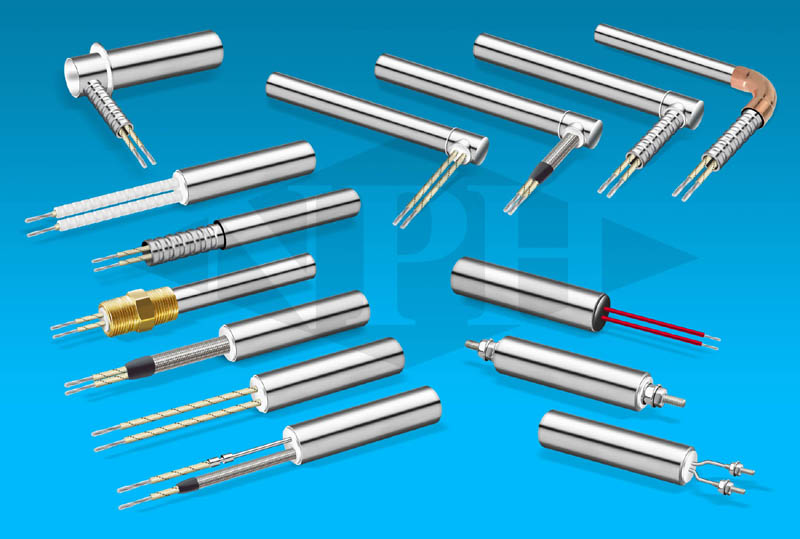

Cartridge Heaters and all the various names for them above are primarily used for heating of all sorts of metal parts by being inserted into drilled holes, but also have uses in the packaging industry and suitable for many other "process industry" applications. Cartridge heaters are either round tube shaped or square/rectangular designs.

The Best Cartridge/Rod heaters are constructed of the following material components:

(i) A thin metal sheathed outer shell/tube (usually made of 304, 316 or 321 stainless steel and incoloy) that actually makes contact with the inside wall of a bore be it in a mold, platen or die and hence transferring its energy via conduction.

(ii) The cartridge heater shell houses the coiled nichrome (nickel/chromium) resistance wire, ceramic insulator and MgO (magesium oxide) insulation. The MgO is compacted via swaging to ensure all empty gaps are filled preventing a short circuit and allowing the heater to transfer its heat quickly and efficiently to the outside wall of the stainless steel shell.

(iii) A welded disc is then applied to the open end of the cartridge after the cartridge heater has been filled with MgO. This prevents the nichrome wire, the MgO and other componets from coming out. In addition, it prevents contamination, such as plastic debris, air, or moisture, to go inside the heater.

(iv) Fiberglass insulated or other lead type insulations are finally installed to complete the cartridge heater. The cartridge heaters might be terminated with the leads coming out straight, or in a right angle. Also, manufacturer must be careful that the leads are not exposed to temperatures higher than the maximum rating for the lead wire. In order to prevent lead wire damage from temperature, movement or contamination, the lead wire can be protected with metal conduit or braided metal.

NPH custom rod heaters can be dual-voltage, three phase, and/or be supplied with a ground terminal. With ten different termination styles, mounting attachments and various optional features, NPH high-density cartridges are widely used in numerous high temperature applications.

NPH custom/bespoke cartridge heaters, custom insertion heaters, split sheath cartridge heaters and square cartridge heaters are available in metric and imperial sizes and are a critical component for major manufactures operating in industries such as plastics, rubber, packaging, food service, military technology and a variety of other industrial applications.

Review Custom/Bespoke Cartridge Heaters Specifications & Tips

-

Best-Cartridge-Heaters-MaintenanceTips-Failure-Prevention.mp3

- Which Cartridge Heaters to Choose From Guide

- Cartridge Heaters, Metric Insertion Heaters-Specifications Brochure

- Cartridge Rod Heaters-Electrical Noise

- Heat Calculations, Watt Densities-Metric Cartridge Heaters

- How To Properly Install Cartridge Heaters-Technical Letter.pdf

How To Order Cartridge Heaters

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide