Coil Heaters, Temperature Control Panels, Mica/Ceramic Band Heaters

PLASTICS PROCESSING INDUSTRY OVERVIEW & ELECTRIC HEATERS GUIDE:

Plastics Blow Molding Facility

Multifoil, Multilayer Blown Film Lines

PVC Pipe Extrusion Line

Plastics Injection Molding Facility

With over 57 years of combined experience, we've become a leading supplier ofelectric heaters, temperature sensors, andtemperature controlsfor plastics processing equipment . Our extensive knowledge has helped us design products that offer you higher productivity and minimize your downtime. In fact, our components are found on OEM equipment for injection molding and extrusion operations around the world.

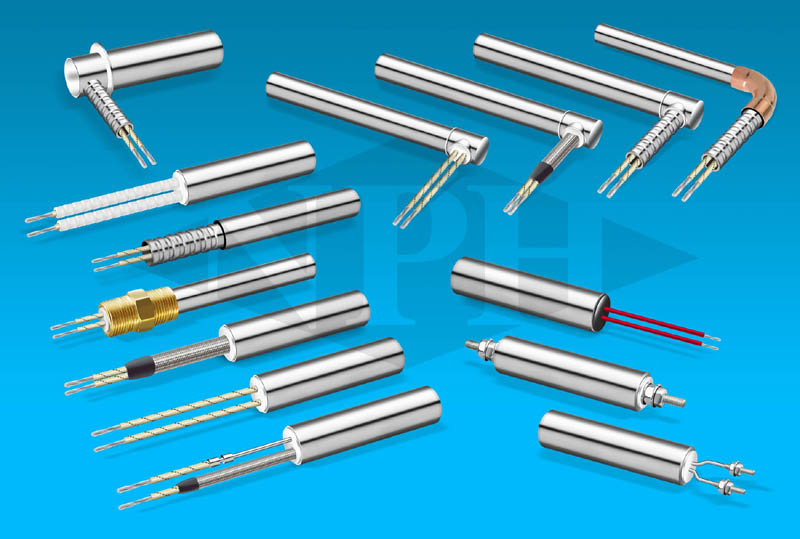

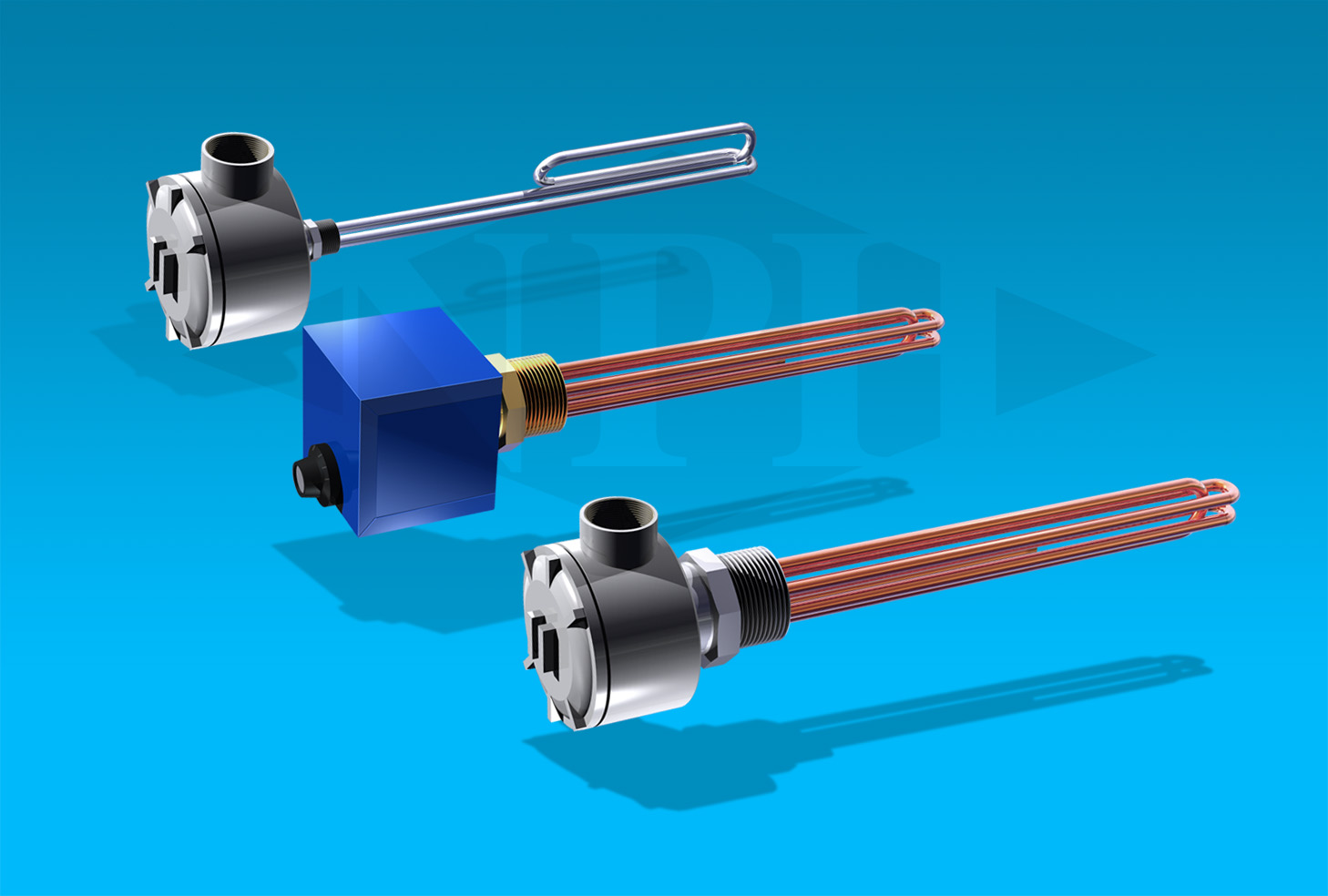

The plastics industry is vast, covering many areas of industry from transport, aerospace, electronics and transportation. Injection mold machines use nozzle heaters to help soften the polymers into final products.The use of thermocouplesand precise digital controllers are also used to maintain target temperatures for each application. Some manufacturers usecartridge heaters that are inserted into steel or aluminum moldsthat heat up large surface areas. Aluminum or steel are excellent alloys as they distribute heat at a much quicker rate than other materials. They are also fairly inexpensive and can have holes pierced to hold thermocouples (type J or K) that would maintain the operating temperature that is required. Bag forming machines often use cartridge heaters to help seal plastic bags and require precise heating so as not to melt the thin layers of plastic.

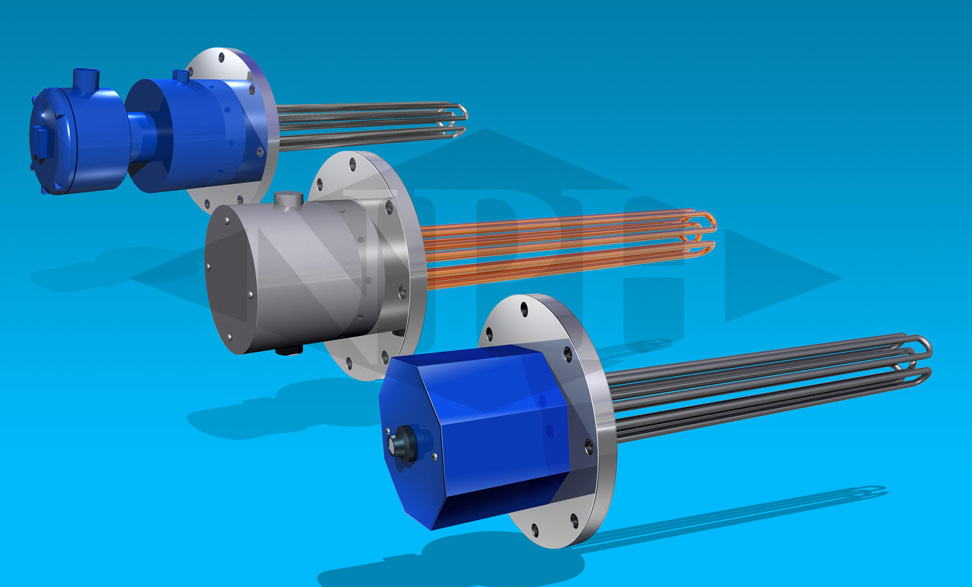

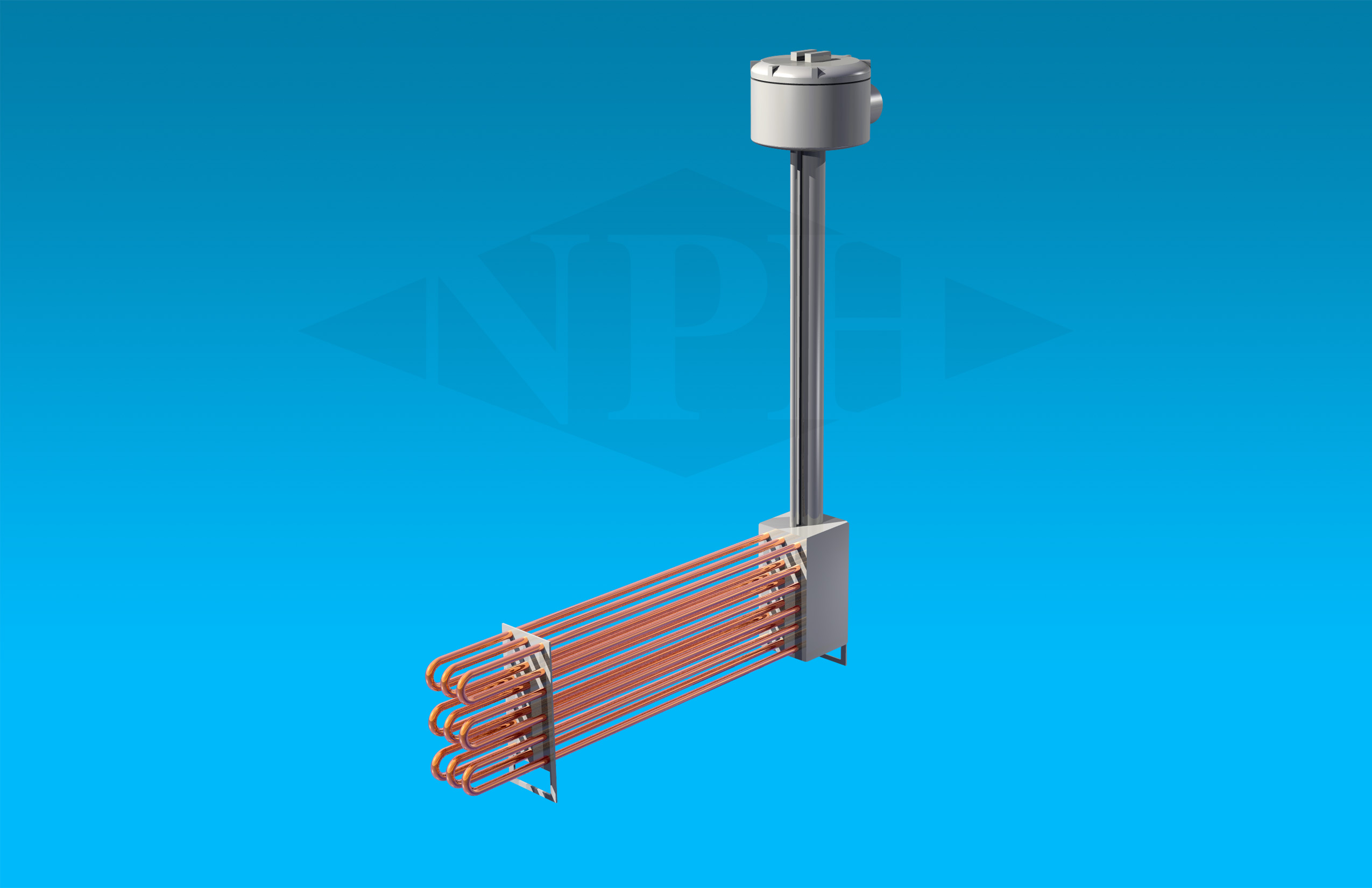

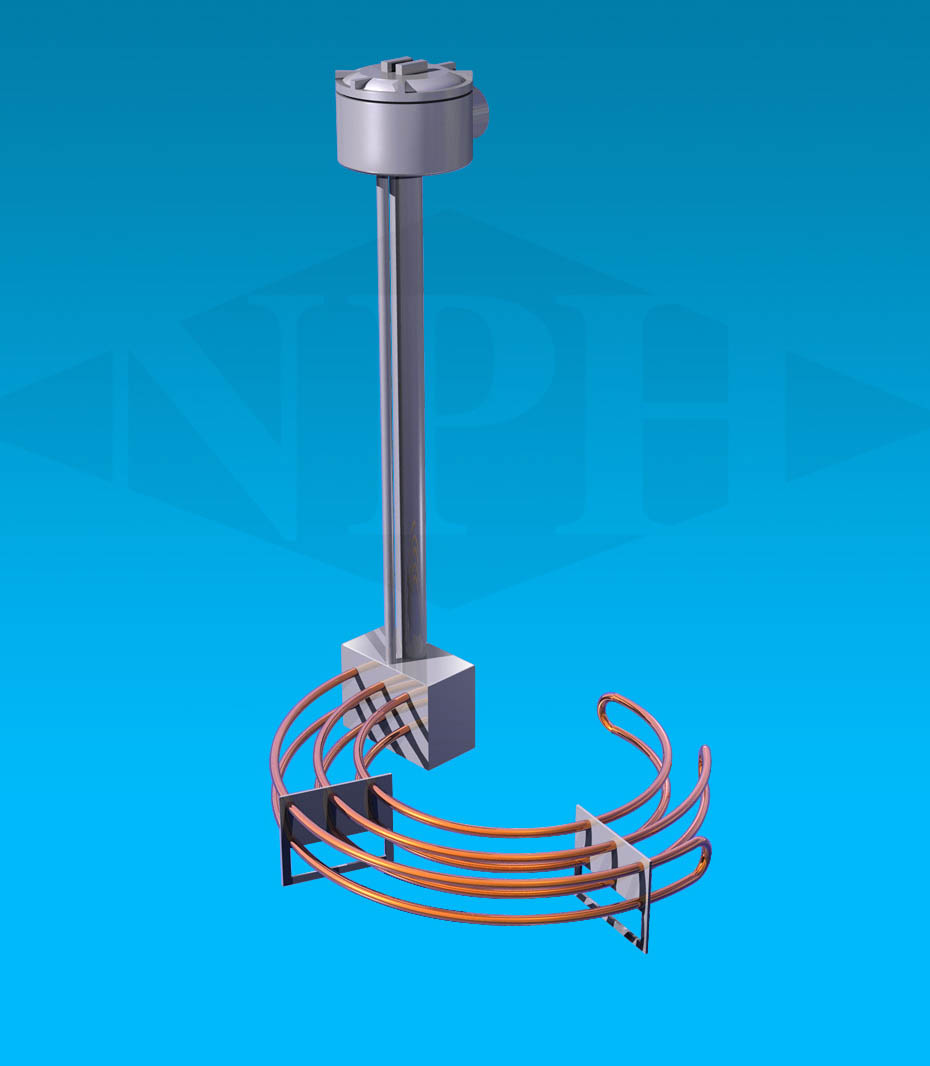

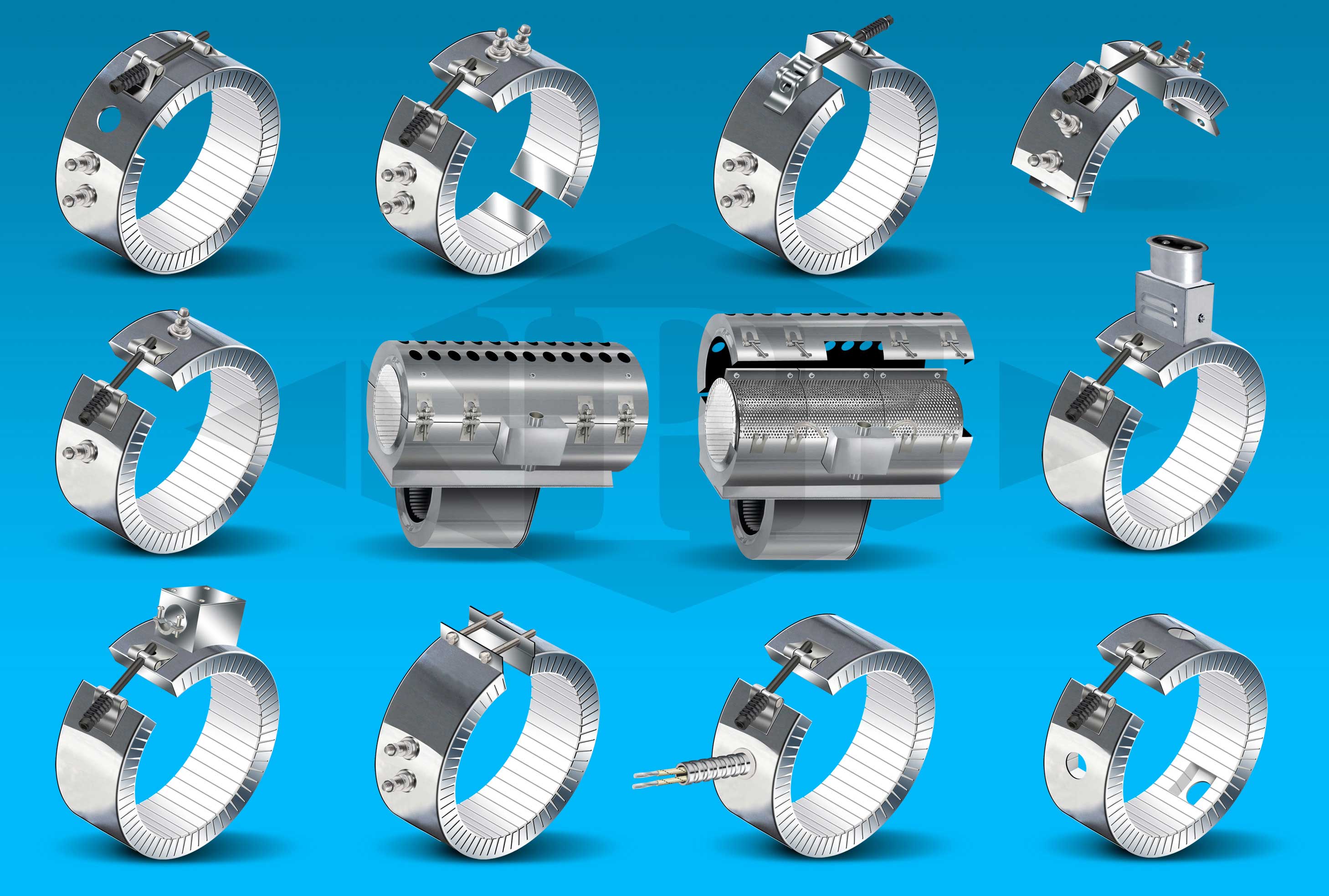

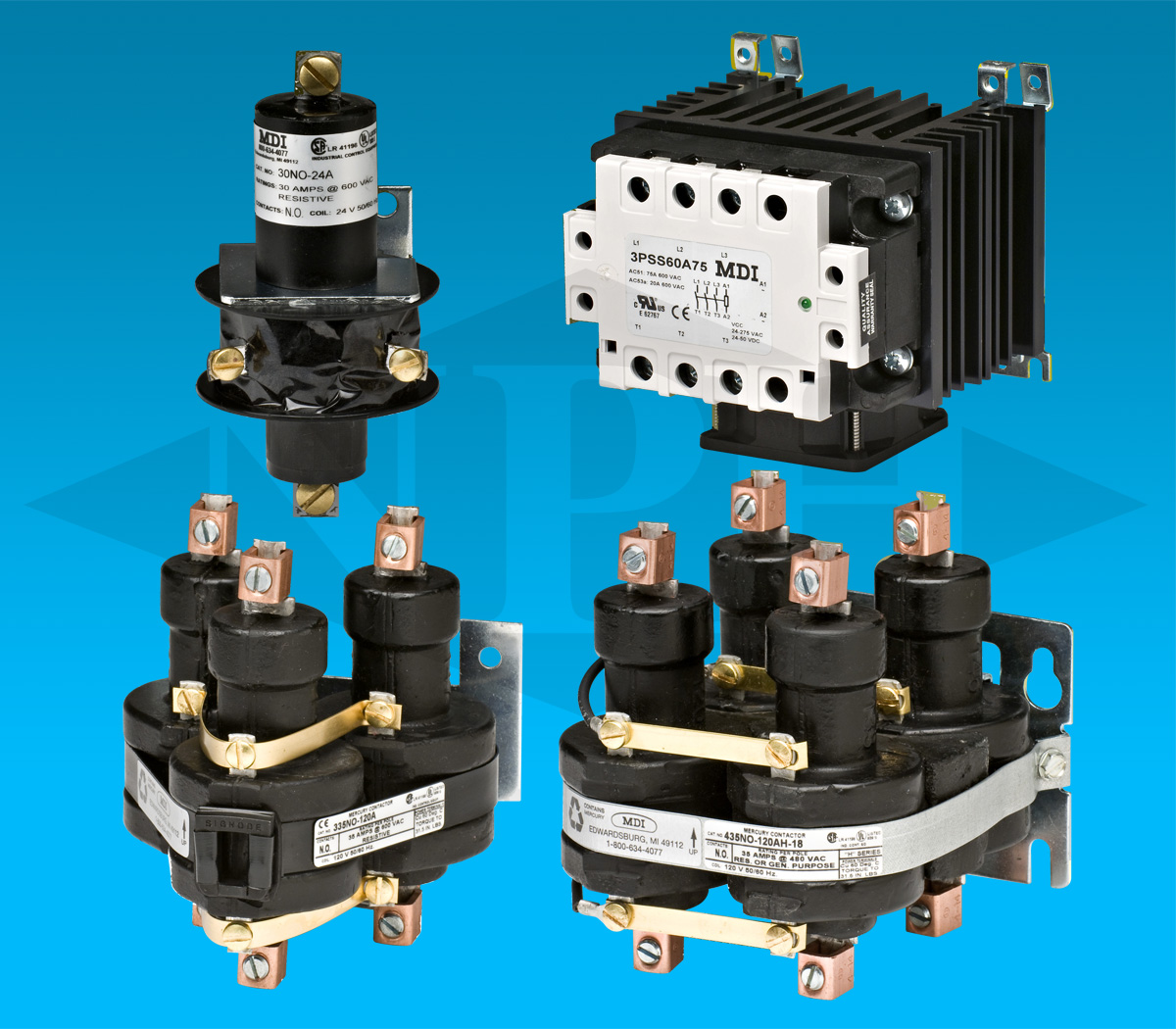

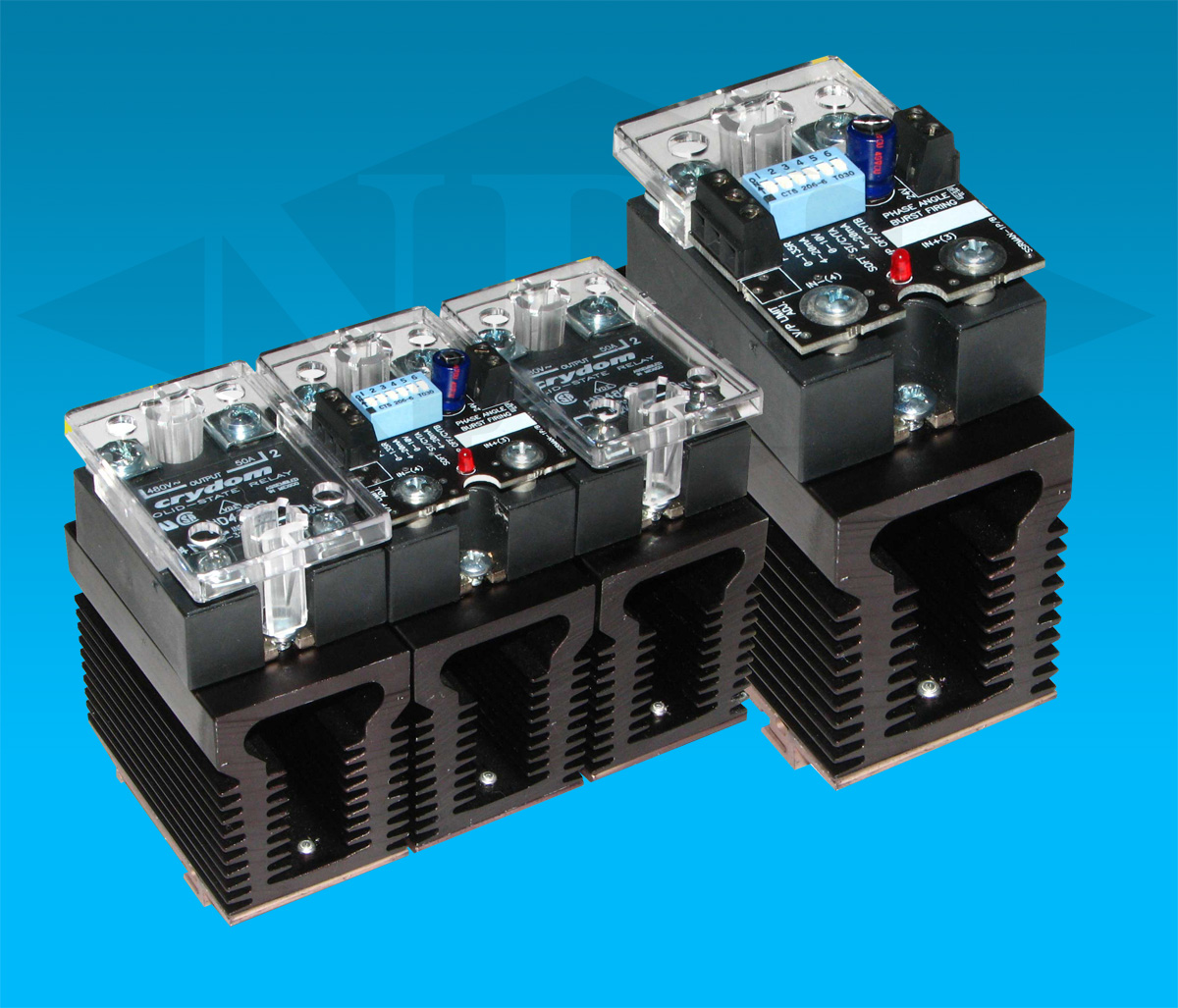

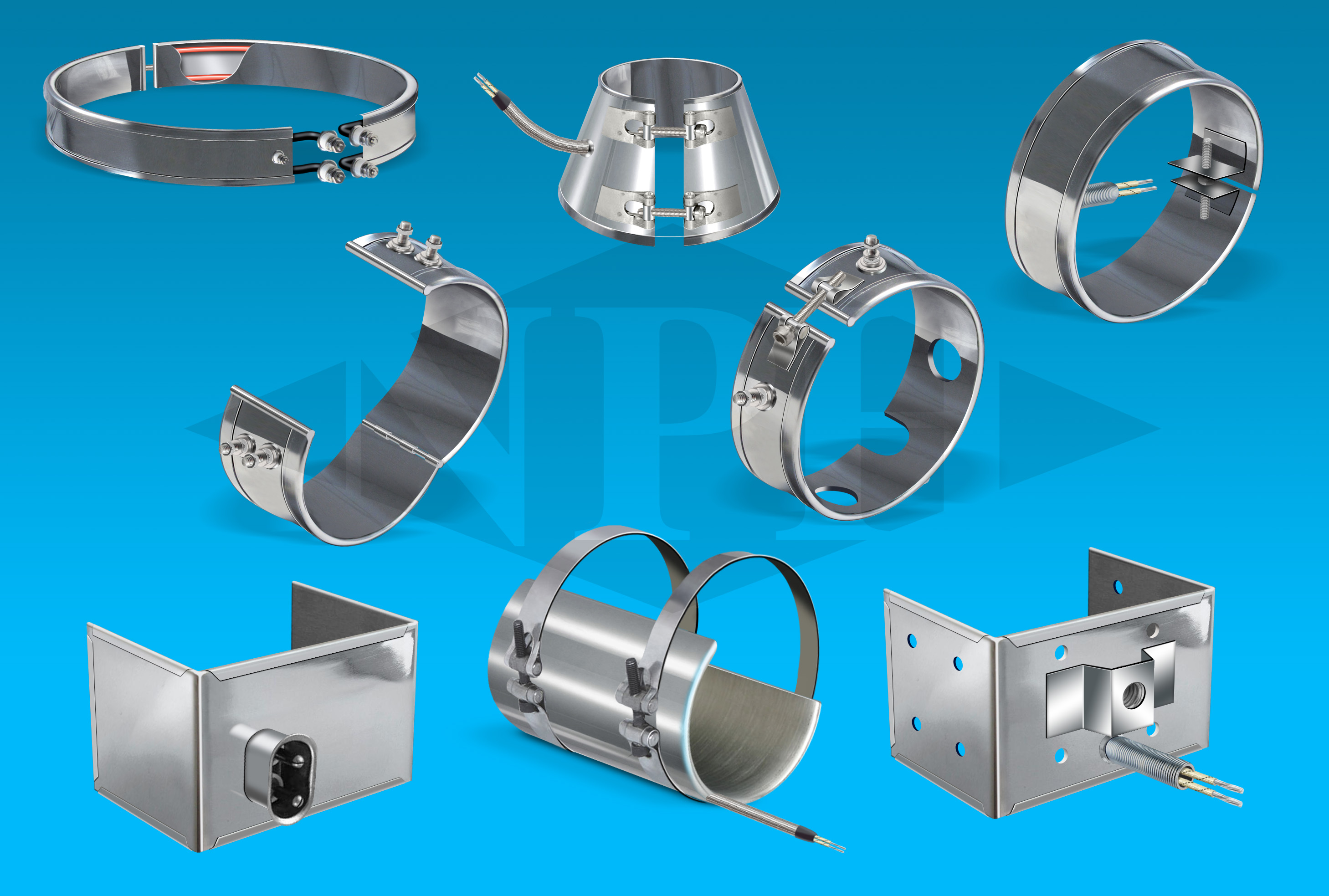

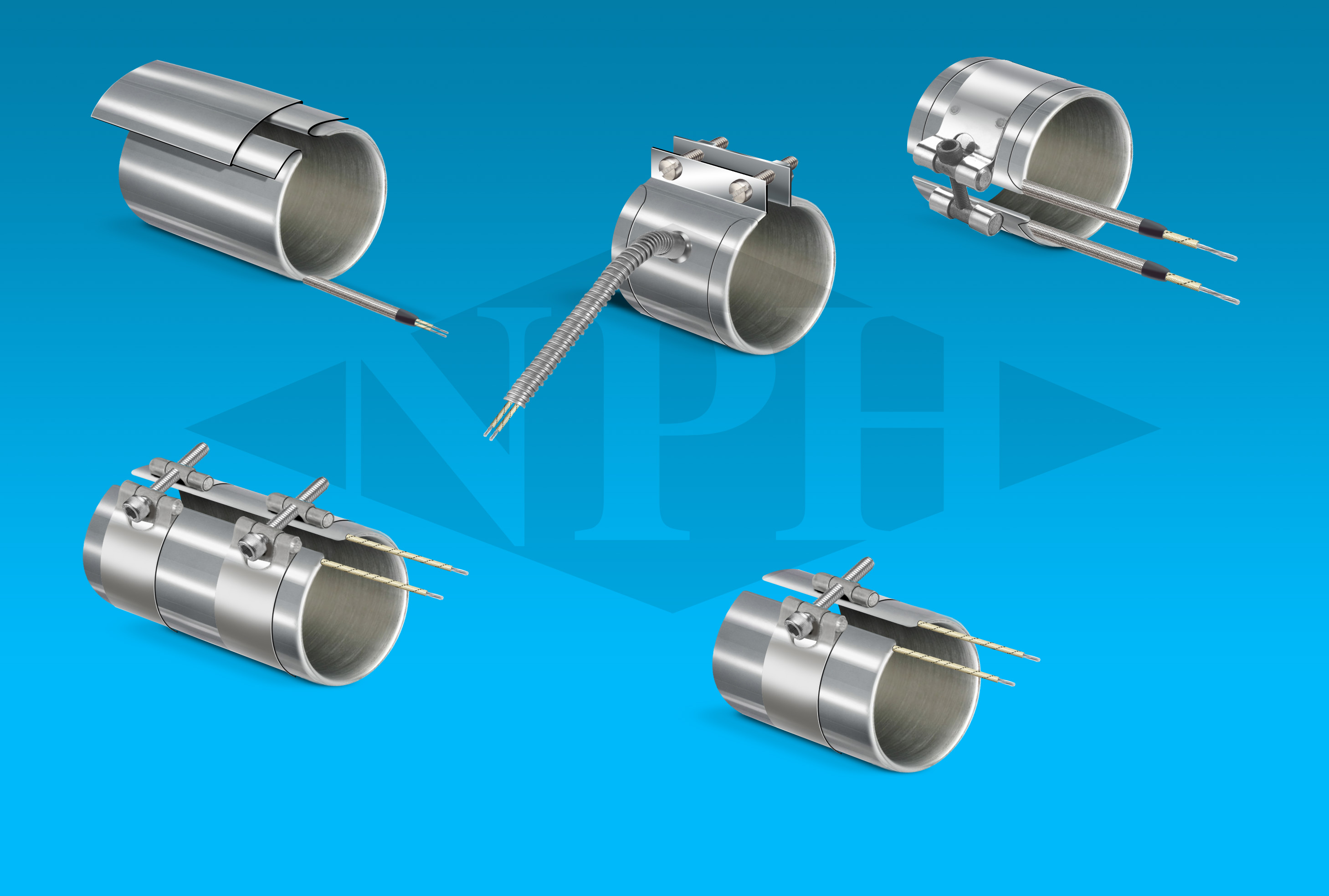

We design, engineer and distributeindustrial grade process electric heaters, along with mica band heaters, ceramic band or knuckle heaters, cast aluminum /bronze heaters, cartridge/ pencil, coil, and platen heaters. We manufacture thermocouples and RTD's. In addition we offerprocess temperature control panelsthat feature the cutting edge of available technology for most Plastic Industry applications.

Blow Molding

NPH engineers, supplies and distributes heater, sensor and temperature control solutions that provide long life for a wide variety of blow molding and blown film applications.

Extrusion

NPH offers custom heater, sensor and control solutions that provide fast thermal response, consistent temperature accuracy with long life for a wide variety of extrusion applications.

Injection Molding & Hot Runner Systems

National Plastic Heater, designs, engineers and supplies heater, sensor and control solutions for injection molding applications including barrel and sprue bushing heating, hopper heating, manifold heating and hot runner systems.

Thermoforming

NPH offers robust radiant heater, temperature sensor and control solutions for the most demanding thermoforming applications such vacuum forming, pressure assist forming, drape and press forming.

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide

.gif)