Nozzle Band Heaters - Custom European Nozzle Band Heaters

Applications:

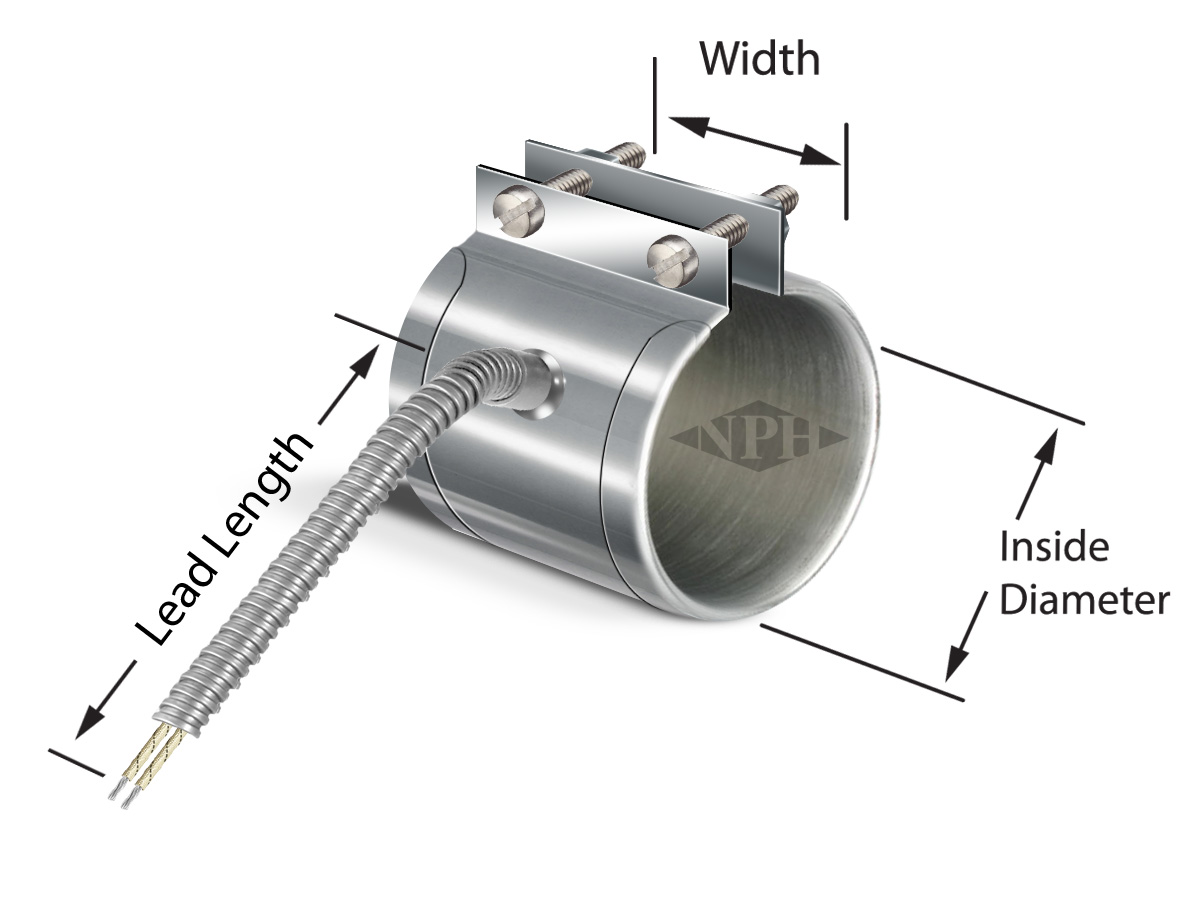

Nozzle band heaters from National Plastic Heater (NPH) are primarily used to heat the nozzles of injection molding machines. In addition other uses include heating of small diameter pipes and uses where heat is required in Life Sciences, Medical R & D apparatus.

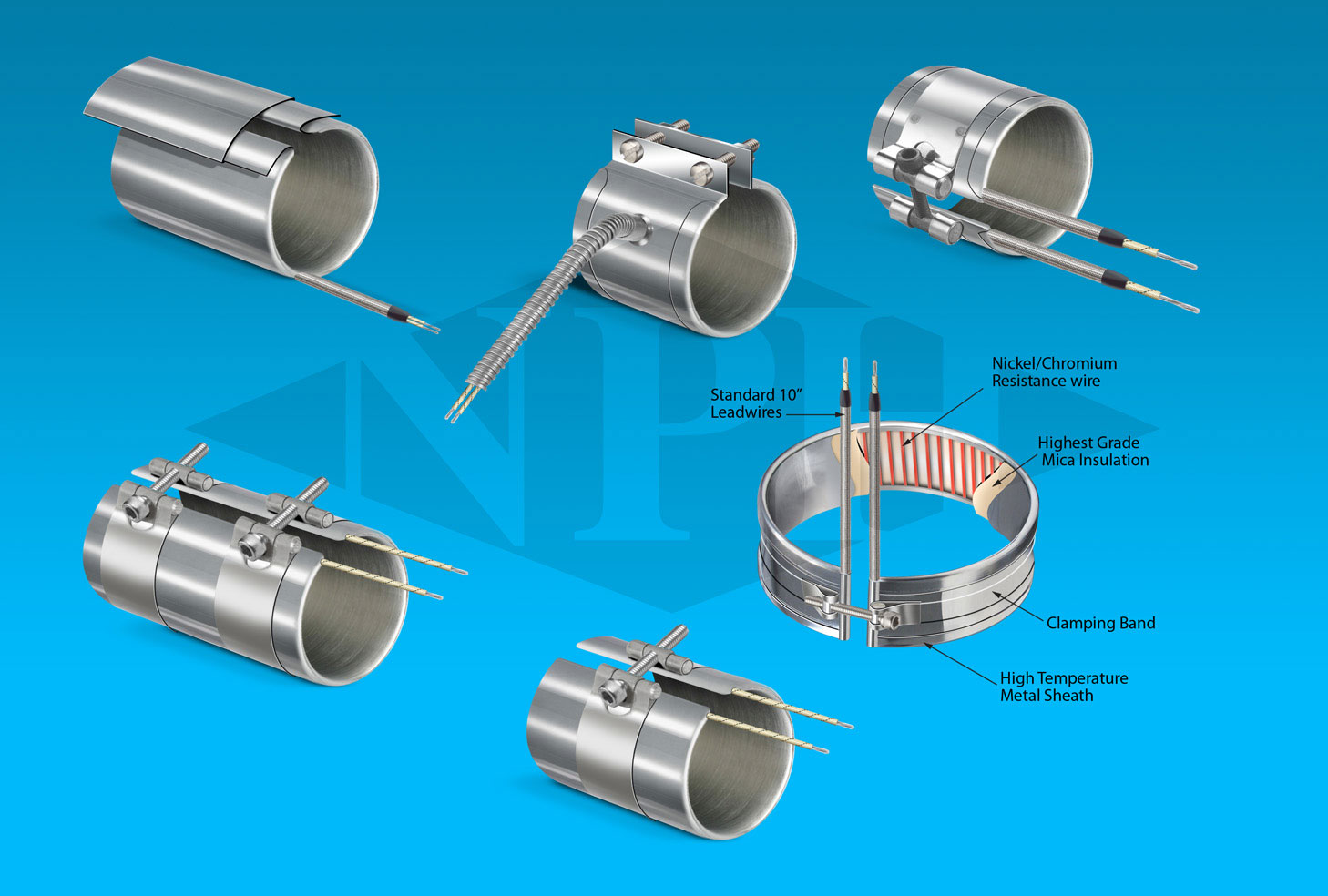

Design and Construction:

Choose a nozzle band heater where the sheet metal has been carefully folded around the insulation to provide a tight seal against penetration by any melted plastic. Cheap nozzle band heaters often scrimp at this point.

Choose the lock-up type. Normally you will replace the existing band with the same type of closure. Most nozzle heater bands have a strap that holds them to the nozzle. Some are bent into a pair of bent-up flanges that are held together by screws. Others use barrel nuts. Shim/Wedge/Key-lock bands are low-profile, to allow them to fit where other bands cannot.

Choose lead-wire length. Most nozzle bands have lead wires. Stock bands normally have relatively short leads to prevent money being wasted by too-long leads. Post terminals are also available, but are more common on bands for barrels

Be sure the heaters fit tightly to the nozzle or barrel. Direct metal-to-metal contact is the most effective method for heat transfer. A loose fit will shorten a heater's life time by allowing a pocket of air that inhibits the transfer of heat. Check bands often because the heating cycle can cause the heaters to loosen over time. A burn spot on the ID of the band is evidence of a loose fit.

We recommend using a little heat transfer compound as a good precaution. A little bit between the heater and the nozzle will help bridge any air gaps. You are still going to want to keep the bands as tight as possible. The heat transfer compound contains metal powders that conduct more heat than air does, but there is nothing like good metal-to-metal contact.

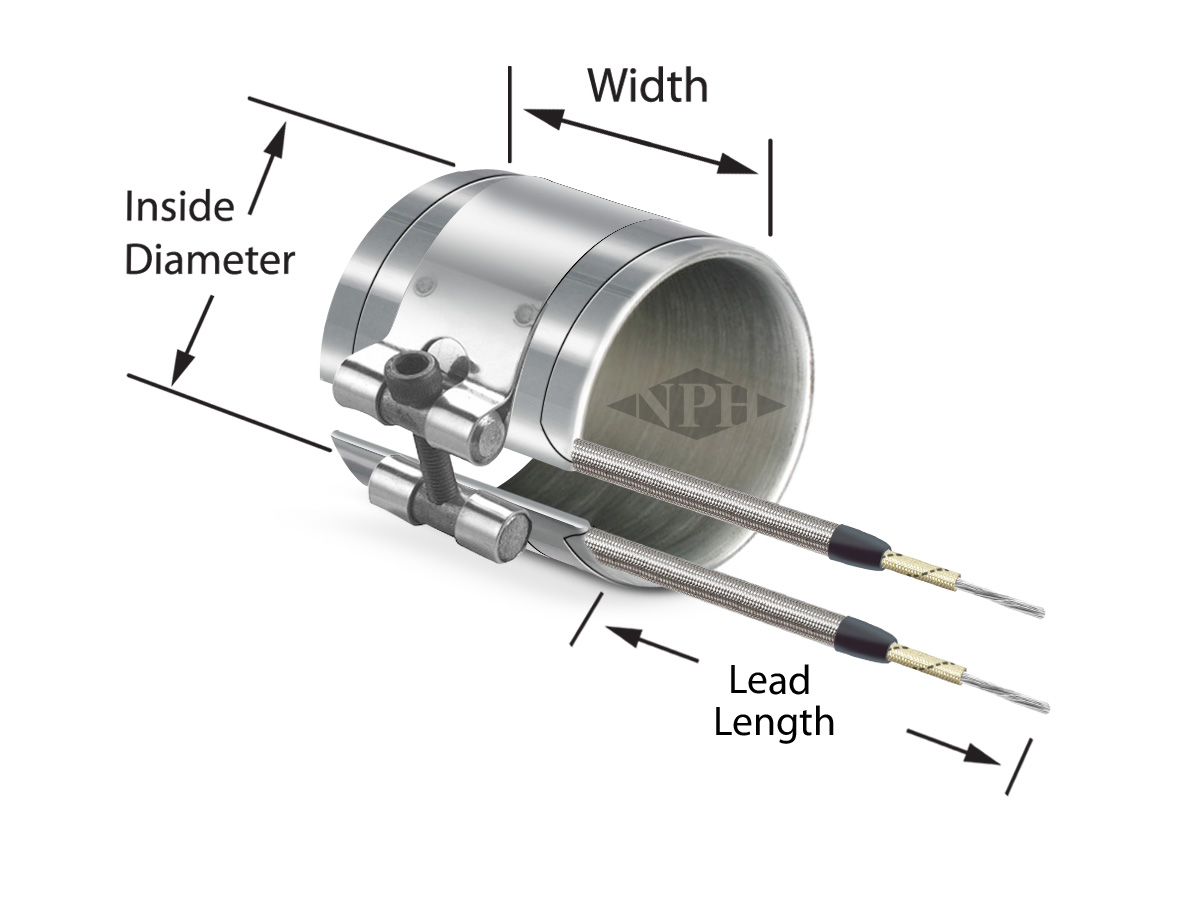

Nozzle Band Heater - Style 1 -Barrel Nut Strap, S.Steel Braided Leads

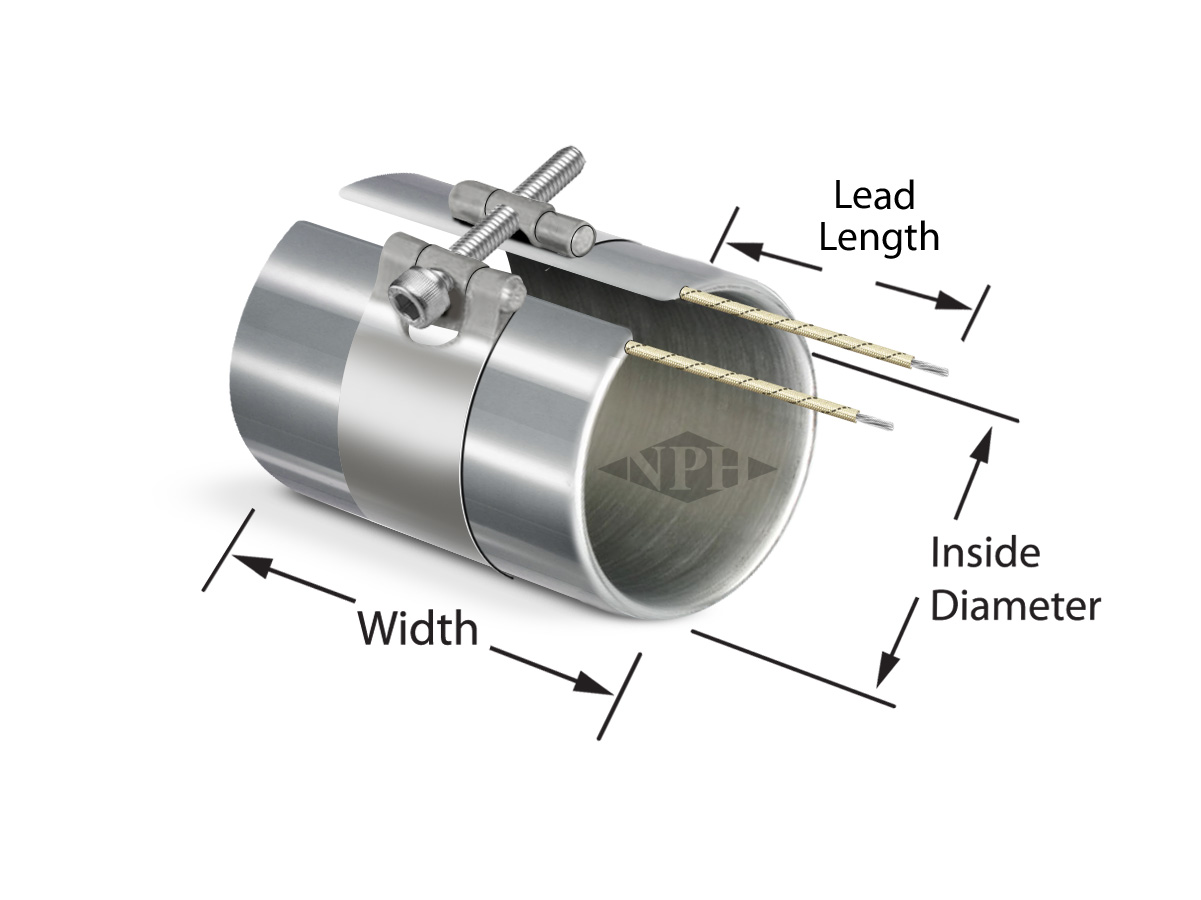

Nozzle Band Heater - Style 2 -Barrel Nut Strap Closure with F/G Leads

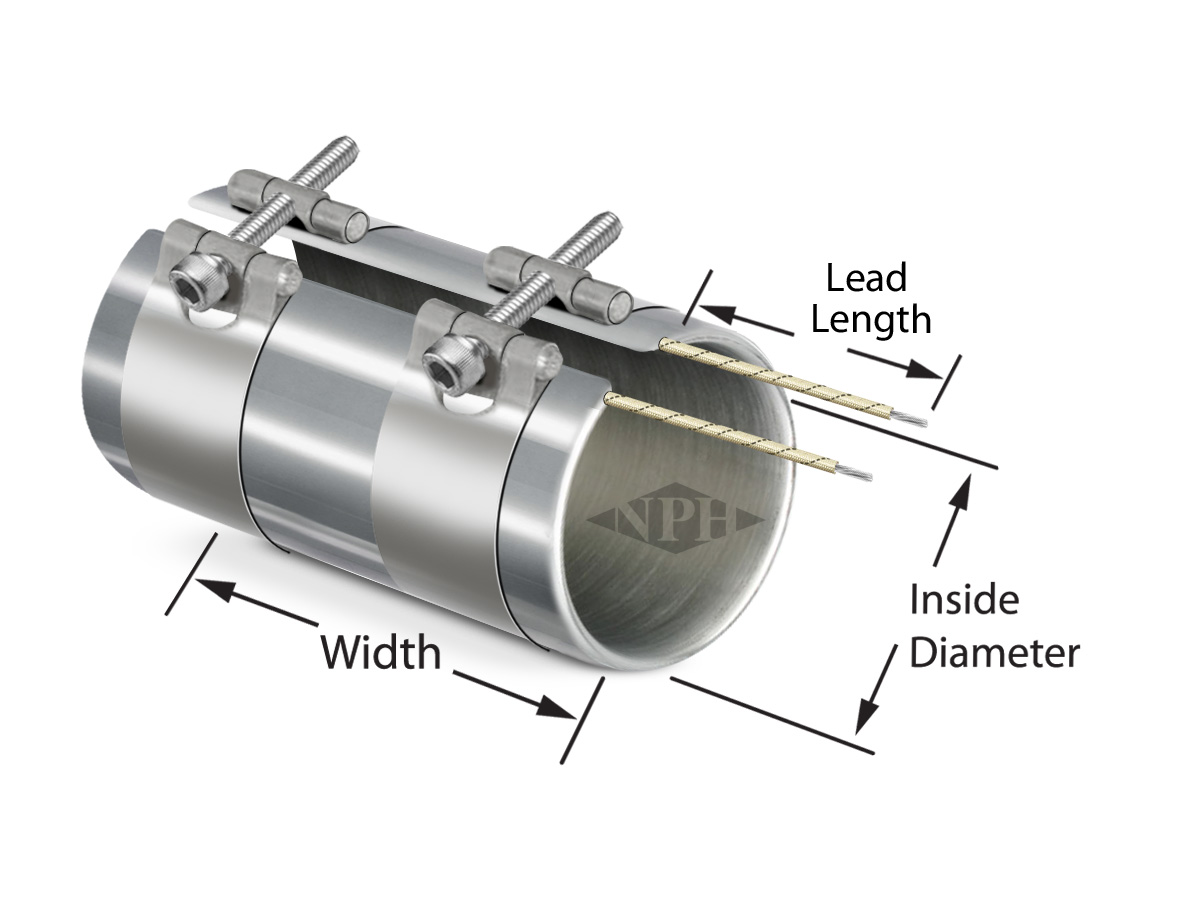

Nozzle Band Heater - Style 3 -Barrel Nut Straps Closure with F/G Leads

Nozzle Band Heater - Style 4

Shim/Key Lock-Up Closure - Style 5 -Nozzle/Pipe Band Heaters

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide