Small Diameter Miniature Pencil Heaters

24 ga ultralead leads, 482°F (250°C)

10" Leads are standard

Leads externally crimped to nickel pins

Minimum 1/4" cold section at lead end is required

24 gauge Teflon® insulated leads, 392°F (200°C)

10" Leads are standard

Minimum 1/2" cold section at lead end is required

High temperature fiberglass leads 842°F (450°C)

10" leads are standard

Minimum 1/2" cold section at lead end is required

Bend is through a required cold section

Standard sheath extension past the bend is 1"

10" plain leads are standard

Other sizes available

10" plain leads are standard

10" braid over 12" Leads are standard

Minimum 1/4" cold section is required

10" cable over 12" leads are standard

Minimum 1/4" cold section is required

Small Diameter Pencil/Cartridge Heaters-Description

Split-Sheath Design

Uniform Heating

Lengths From 1/2" Inch to 6 Inches

1/8" and 4mm Diameters

Unique Hot Tip

Patented high-temperature design provides these advantages:

- When energized, thepatented split-sheath expandsinto contact with surrounding bore for maximum heat transfer, fast response.

- When de-energized, thesplit-sheath contractsfor easy, slide-out removal. Sunrods are guaranteed never to sieze in the bore.

- Uninterruped hot zone andfully heated tipprovides unmatched heat distribution without cold spots. (See upper photo).

- Slender continuous leadssimplify wire management. High flexibility allows free motion when heating "floating" components.

- The result is a miniature cartridge heater offering longer life, uniform temperatures, and easy installation in the smallest devices.

NPH's 1/8" Cartridge Heater with Swaged-In Leads-Simplifies Wiring

Extending Miniature Heater Life:

Designing cartridge heaters with reduced watt-density multiplies service life.

The industry-standard warrantee for electric cartridge heaters is 2000 hours, or one year on single shift. This is a reasonable life expectancy for many applications. But some applications demand much more. Life expectancies of five, seven or even ten years are not unreasonable for some mission-critical applications:

- Blood warmers used in medical theaters must never fail

- Battery conditioners for EVA spacesuits on the International Space Station must last ten years before replacement, due to payload costs

- Here on earth, high throughput semiconductor chip testers must operate without significant downtime for the 5 year life of the equipment. For these applications, a service life of 50,000 to 90,000 hours is a requirement that is both reasonable and attainable.

How can it be done?

For every heater power loading (See "Calculating Watt-Density", at bottom) there is a maximum operating temperature that will guarantee 2000 hours life. This is the "Critical Temperature" for that power loading. (See chart below).

Power Chart - System Temperature versus Maximum Watt-Density

| Critical Temperature (F): 200 300 400 500 600 700 800 900 1000 |

| Maximum Watt-Density : 365 345 310 275 245 225 170 150 130 |

Go above the Critical Temperature by 100 degrees and life will be cut to a third, to 666 hours. But go below it by 100 degrees and heater life will be tripled, to 6000 hours! We can use this relationship to determine the watt-density at a given system temperature that will yield thousands of hours of extra life.

For Example...

Maximum Watt-Density Lowered Watt-DensityHow Do You Reduce Watt-Density?

Your heater watt density may not have to be reduced. Many miniature heating applications inherently require relatively little wattage, due to their small mass. This often results in a minimal power loading on a 1/8" miniature heater. In these cases, miniature cartridge heaters are often under-loaded by 200 to 400 degrees, relative to the Critical Temperature. Their 2000 hour life expectancy* may be multiplied up to 81 times!

Increasing Surface Area to Reduce Watt-Density1. Maximize your heater length. Increasing the length of a 1" heater to 1 �" (just a �") can increase the active area* by 33%, reducing power loading by 25%.

2. Consider using more heaters. Two heaters dividing the load will reduce watt-density by 50%.

3. Take advantage of any available space to install a supplemental heater. Adding a �" long heater to an existing 1" heater can reduce power loading by 25%.

Calculating Watt-Density

Watt-density is the power loading of the heater, expressed in watts-per-square-inch of active heater surface.

The formula for active heater surface is: (Heater Length x Cold End Length) x Diameter x Pi. For a 1/8" diameter by 1" long heater it is: (1.00 - 0.25) x .38, or .285 square inches.

The formula for watt-density is: Wattage / Active Heater Surface For 1/8" diameter by 1" heater at 80 watts, this is: 80 watts / .285 in sq or 270 watts/sq inch.

Small Diameter, Miniature Cartridge Heaters Selection Guide

The key questions which need to be answered before selecting a cartridge heater for your application are:

- How much wattage is required?

- What voltage will be used?

- What is the heated length? What is the overall length?

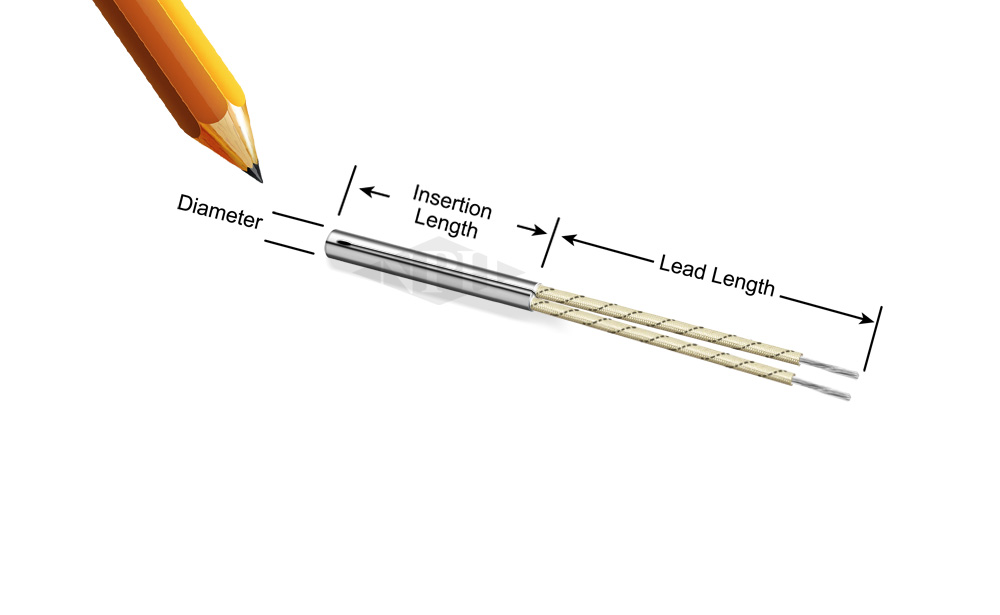

- How long are the heater leads or what is the lead length required?

- What is the dimentions of the cartridge heater?

- What is the ambient temperature the cartridge heater will see?

- What is the maximum temperature required from the heater?

- How quickly do you want to reach your operating temperature or set point in hour/minutes?

- What is the type and weight (in lbs.) of the material you want to heat?

- Special Modifications

How To Order Cartridge Heaters

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide