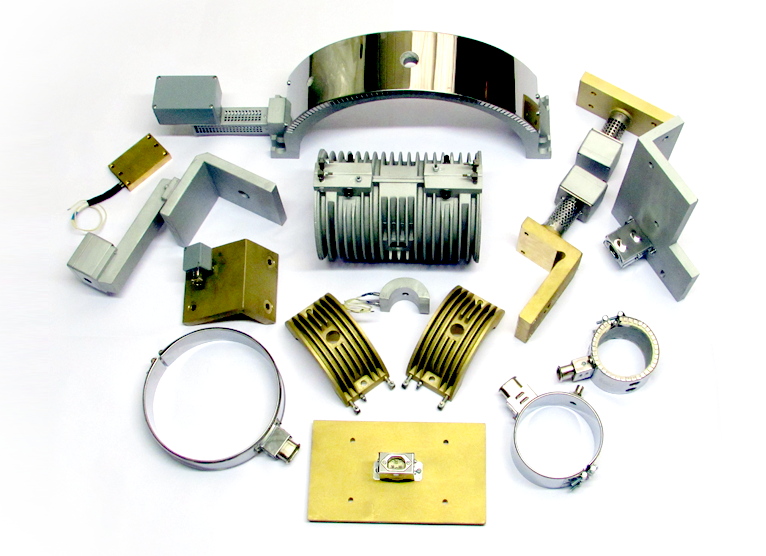

Davis Standard Bronze Heaters, Davis Standard Replacement Bronze Heaters, Custom Cast In Bronze/ Iron Heaters for Plastics Extruders

Custom Cast in Bronze/Brass/Iron Heaters For Plastics Extrusion, Pipe Heating and Other Applications

Heat and Water Cooled Cast in Bronze/Brass/Iron and Aluminum Heaters:

Cast band heaters (Cast-in) are available in Aluminum (850ºF), Brass (1200ºF), Bronze (1350ºF) and Cast Iron (1850ºF) . Cast aluminum and cast in bronze water-cooled units are the most common. The castings contains both Incoloy sheathed heating elements and stainless steel cooling tubes. The heaters are available with bolt clamping or separate stainless steel strap clamping. Heating elements are supplied standard with threaded stud terminals for electrical connections. Sheet metal terminal boxes and other termination options are available. The stainless steel cooling tubes can be supplied with a variety of fittings if required, but are supplied with no fittings in the standard design. Holes for temperature sensors melt pressure transducers and vents are available. These heaters are all custom, made to order items, so please feel free to contact our sales staff for replacement heaters or to help you design the best heater for your application.

Cast In Process Manufacturing Guide: Making your Cast In Bronze/Brass Heaters Below:

Cast In Heaters Being Machined

Machined Cast In Heaters Being Assembled (Extrusion/Pipe Heaters-Cast In Bronze/Brass/Aluminum and Iron)

Heat and Air Cooled or Finned Cast In Bronze/Brass Cast In Heaters

Finned Cast Heaters contain Incoloy sheathed elements to provide the heating. The fins offer a large surface area for airflow to act as the cooling medium. These heaters are intended to be used with sheet metal or cast shrouds which are sold separately. The heaters are available with bolt clamping or separate stainless steel strap clamping. Heating elements are supplied standard with threaded stud terminals for electrical connections. Sheet metal terminal boxes and other termination options are available. Holes for temperature sensors melt pressure transducers and vents are available.

"L" Shaped Cast in Bronze/ Brass/Iron Heaters

L Shaped Bronze Heaters

L Shaped Cast In Brass and Aluminum Heaters With European Plugs/Connectors

High Temperature Bronze/Brass Cast In Heaters

NPH "L" Shaped Cast-In Heaters are typically used on square and rectangular twin screw extruder barrels in compounding and plastic resin manufacturing applications. Due to high shear rates, which are common in this process, extreme operatingtemperatures and high watt densities are frequently encountered. For these reasons National Plastic Heater provides "L"shaped heaters in bronze or brass alloys, which are capable of withstanding high temperatures at higher watt densities.In the case of applications requiring lower temperatures and lower watt densities, aluminum alloys can be used. Aluminum castings are desirable as they have greater thermal conductivity and weigh substantially less than their bronze or brass counterparts, allowing for greater ease of installation.

For mounting purposes, the "L" Shaped Cast In Bronze/Brass heaters can be designed with 45° flanged ear extensions that are bolted and drawn together, or can be made with through holes machined into the casting body to bolt directly onto the barrel itself. Thermocouple and transducer holes or other special features can be accommodated as well.

To enhance the cooling capabilities, or to be used in place of integral feed screw cooling, "L" shaped heaters can be manufactured with cast-in cooling tubes to satisfy liquid cooling requirements. This feature allows processors the ease of changing a single unit at a time, thus representing a far less time-consuming and less expensive alternative should a cooling line become clogged or severely restricted.

- Moisture resistant terminal housing which is available in a variety of different styles and mounting arrangements

- Choice of terminal protection housings

- Elevated temperature terminations and enclosures. Prevents premature heater failure due to accelerated corrosion or

- Cast-In Aluminum Alloys for applications requiring lower temperatures and less watt density

3/8" or 1/2" O.D. cooling tubes for liquid cooling

- Non-Exposed cooling tubes, eliminates cracked and broken cooling tubes.

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide