NATIONAL PLASTIC HEATER, SENSOR & CONTROL INC. Industrial Process Heating, Temperature Sensing & Control Technology For Industry |

| Toll Free: 1-877-674-9744 | ||

| Visit Our Online Store To Purchase Our High Temperature European Connectors, High Temperature Accessories and Miniature Cartridge Heaters | ||

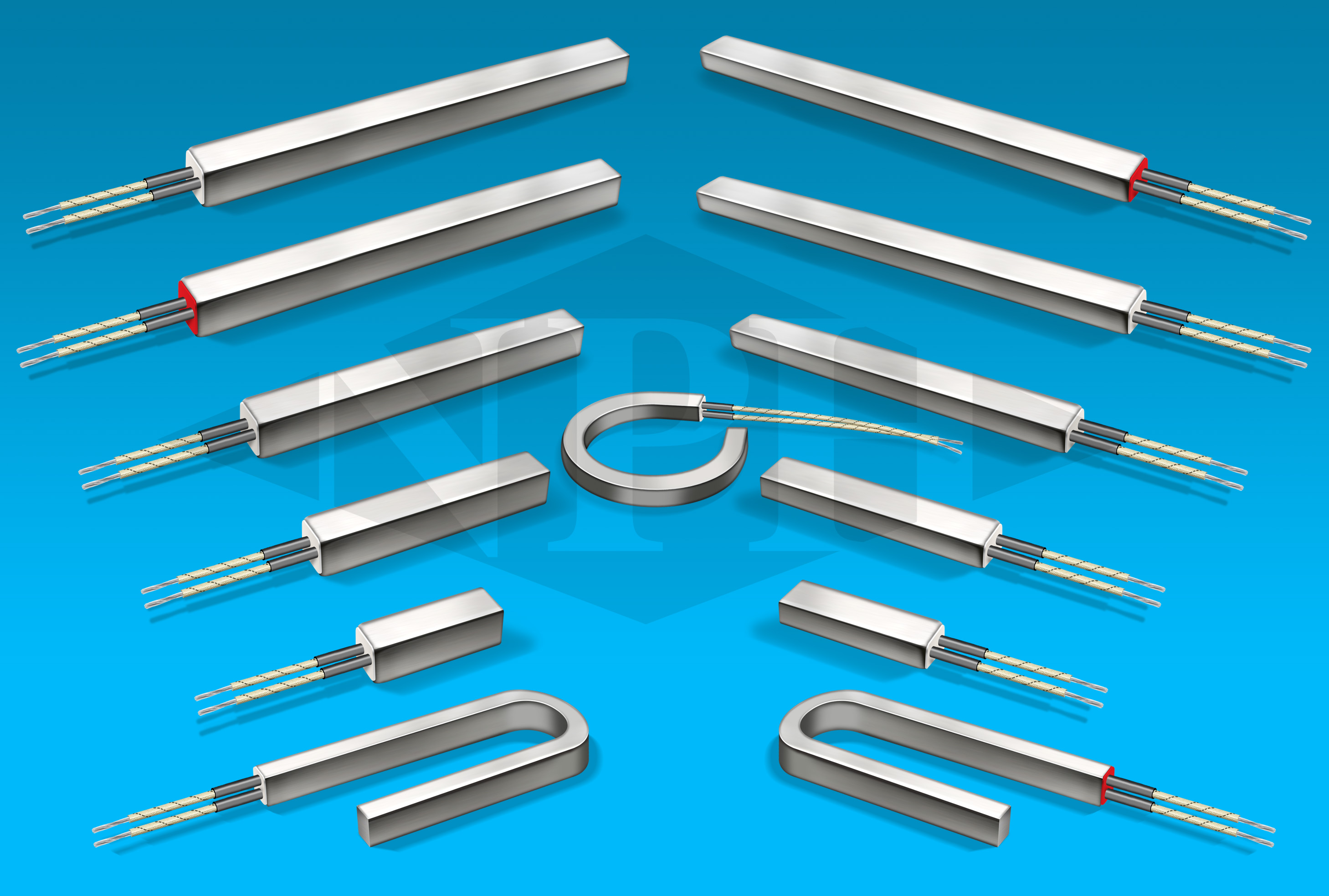

Square Cartridge Heaters, Square Metric Heaters, Square Mold Heaters, Rectangular Cartridge Heaters And Square Channel Heaters For The Plastics, Injection Molding, Extrusion Die, Food Service And Packaging Industries

Square Cartridge Heaters, Rectangular Insertion Heaters

Square Cartridge Heaters-Imperial and Metric Group

Square Cartridge Heaters–Description Guide

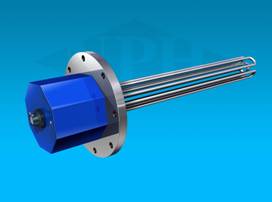

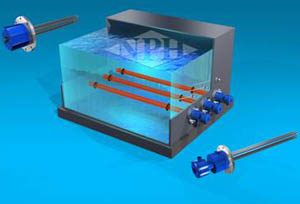

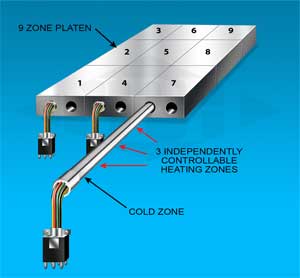

The NPH square cartridge heater provides a cost effective, high performance solution for a variety of standard and special process heating requirements. The square configuration simplifies wiring and installation while optimizing performance in a wide range of solid, liquid, and gas heating applications. Tooling applications are particularly well served by the square cartridge heater approach. Typical square cartridge heating applications include platens, molds, sealing bars, sealing plates and dies. Versatile slot style mounting simplifies installation in small tooling components such as bushings and nozzles and is particularly useful when leads must exit at a specific location on the component surface.

Versatile, Reliable and Cost Effective

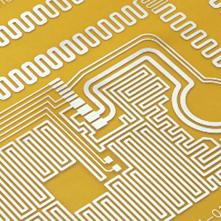

The use of square cartridge heaters clamped into milled slots on the tool surface has become particularly cost effective with the advent of modern CNC machining. Square heaters clamped into close fitting milled slots provideoptimum heat transfer to the application while permitting easy heater removal for system cleaning or maintenance. Swaged square cartridge heaters provide 4 to 5 times the watt density of current square and rectangular cartridge and strip heaters allowing use of smaller and fewer heaters per application. For a given projected heater area on a plate surface, a properly clamped square cartridge can supply as much as 25 percent higher wattage than a round cartridge.

The versatile milled slot mounting method allows heater leads to exit the application at any desired location and permits routing of leads from multiple heaters to a single exit area. Temperature sensors and leads can be incorporated directly into the heater mounting system, reducing wiring complexity in both single and multiple zoned heating applications. Heater lead termination areas can be readily isolated from potential contaminants and protected from physical abuse. Heating characteristics can be adjusted by adding heaters or additional control zones at key locations with only minimal tooling modification. Uniform heating of profiled surfaces and irregular shapes is easily accomplished using the milled slot square cartridge mounting method.

Square cartridge heaters installed in aluminum, brass or bronze blocks can readily replace many costly cast heater configurations requiring extended delivery time. In the event of damage the assembly can be repaired rather than replaced.

The versatile milled slot mounting method allows heater leads to exit the application at any desired location and permits routing of leads from multiple heaters to a single exit area. Temperature sensors and leads can be incorporated directly into the heater mounting system, reducing wiring complexity in both single and multiple zoned heating applications. Heater lead termination areas can be readily isolated from potential contaminants and protected from physical abuse. Heating characteristics can be adjusted by adding heaters or additional control zones at key locations with only minimal tooling modification. Uniform heating of profiled surfaces and irregular shapes is easily accomplished using the milled slot square cartridge mounting method.

Square cartridge heaters installed in aluminum, brass or bronze blocks can readily replace many costly cast heater configurations requiring extended delivery time. In the event of damage the assembly can be repaired rather than replaced.

Square Cartridge Heaters - Standard, Special Purpose and Custom Manufactured.

The NPH square swaged cartridge design and manufacturing process is geared to provide quick delivery on both standard and application oriented versions of the NPH square cartridge heater.

Standard-Square Swaged Cartridge Heaters

Our extended range of imperial square cartridge cross sectional dimensions was established to provide our customers with a full service source for virtually any square cartridge cross section required. A wide assortment of lead and seal options, construction variations and mounting options ensures compatibility with both new and existing heating applications.

- Extended imperial cross sectional dimension range

- All combinations of sizes and ratings available

- Many popular lead and seal options

- Standard integral sensor styles

- Wide range of standard mounting options

- Many standard construction options

Special Purpose-Square Swaged Cartridges

NPH manufactures a variety of special purpose square cartridge heaters for many common and specialized heating applications. These special purpose cartridges are designed to provide the optimum physical, thermal and electrical characteristics for the precise application for which they were designed.

- Runnerless injection mold heaters

- Thermoset mold and platen heaters

- High performance heaters

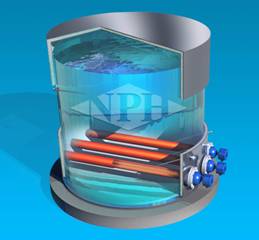

- High wattage immersion heaters

Custom-Square Swaged Cartridge Heaters

Custom square cartridge heaters can be manufactured to customer specifications or can be engineered to satisfy the specific requirements of special applications. Custom square cartridges often consist of standard units with relatively minor design modifications but may include a variety of the special features noted below.

- Unique application oriented lead configurations

- Special non-standard cross sectional dimensions

- Extended temperature and wattage performance

- Corrosion resistant and exotic sheath materials

- Low voltage element designs

- Special multiple sensor options

- Unique custom engineered construction options

- Special purpose mounting fittings

Square Cartridge Heaters Design and Construction Features:

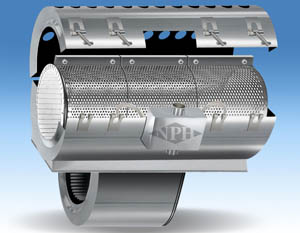

Premium Quality Element Wire. Nickel-chromium resistance wire is precision wound on a high purity ceramic core to optimum computer generated gauge and pitch specifications. Element wires overlap the internal pins and are swaged into a metallurgical bond for optimum connection life.Superior Element Positioning. Precise centering of the square element assembly insures optimum heat uniformity around the cartridge periphery. The square element configuration positions the element wire in close proximity to the cartridge sheath providing rapid and efficient heat transfer to the application.

Densely Compacted Ceramic Insulation. The magnesium oxide ceramic insulation is compressed to near theoretical density in order to provide the best combination of heat transfer and dielectric strength. This dense mass of compacted ceramic also provides maximum resistance to shock and vibration.

High Temperature Alloy Sheath. Available sheath materials include various stainless steel and incoloy compositions. Additional metal sheath compositions can also be supplied as applications dictate.

Welded End Seal. A square metal end disc of the same alloy as the sheath is heli-arc welded into the end of the cartridge. This seal weld provides the positive seal required for liquid heating applications as well as eliminating the possibility of contaminants entering the disc end of the cartridge.

Durable, Heat Resistant Lead Systems. The standard high temperature leads exit from the cartridge through a protective ceramic end cap. The lead insulation is recessed well into the cap to eliminate any possibility of exposing bare wire when bending the leads sharply at the lead end. Standard leads consist of ten inches of UL approved stranded wire. The lead wire insulation is UL rated for 842°F/450°C continuous operating temperature.

A wide variety of other standard and special purpose lead styles are also available.

A wide variety of other standard and special purpose lead styles are also available.

Square Cartridge Heaters Selection Guide

The key questions which need to be answered before selecting a square cartridge heater for your application are:

- How much wattage is required?

- What voltage will be used?

- What is the heated length? What is the overall length?

- How long are the heater leads or what is the lead length required?

- What are the the dimentions of the square cartridge heater?

- What is the ambient temperature the square cartridge heater will see?

- What is the maximum temperature required from the square cartridge heater?

- How quickly do you want to reach your operating temperature or set point in hour/minutes?

- What is the type and weight (in lbs.) of the material you want to heat?

- Special Modifications

How To Order Cartridge Heaters