NATIONAL PLASTIC HEATER, SENSOR & CONTROL INC. Industrial Process Heating, Temperature Sensing & Control Technology For Industry |

| Toll Free: 1-877-674-9744 | ||

| Visit Our Online Store To Purchase Our High Temperature European Connectors, High Temperature Accessories and Miniature Cartridge Heaters | ||

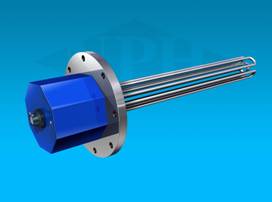

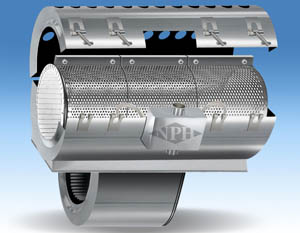

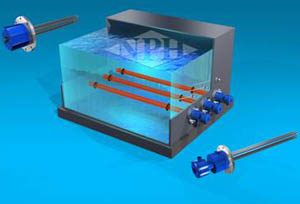

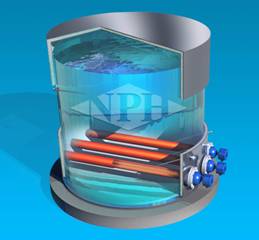

Industrial Oven Solutions Offering Custom Energy Efficient Halogen Ovens For The Thermoforming, Packaging And As Heaters For Paint Curing, Printing And Drying. National Plastic Heater Specializes In The Engineering And Supply Of Ovens, Control Solutions And Components For A Vast Array Of Other Industries As Well. Medium Wave Quartz Infrared Ovens.

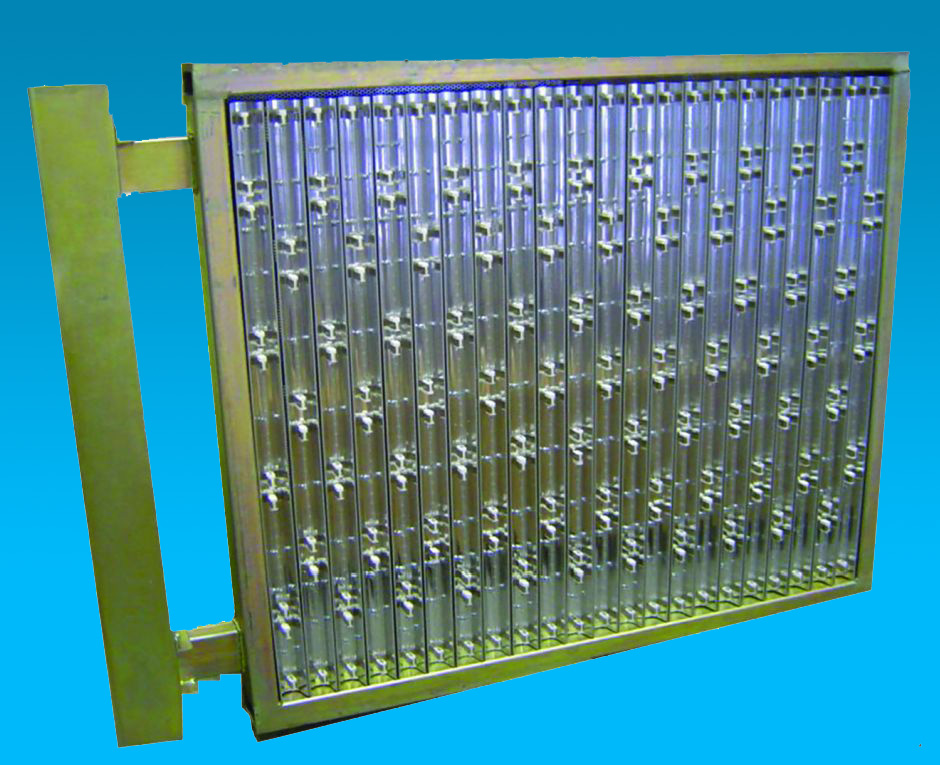

Halogen Ovens and Panels

Halogen Ovens and Panels

Custom Halogen Ovens and Panels

Short (Near) Wave Quartz Tungsten/Halogen Emitters:

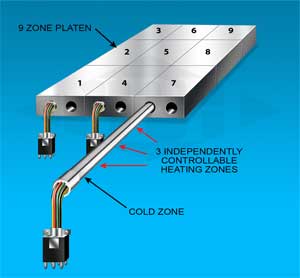

Short wave electric infrared heating elements employ a high intensity tungsten filament to transfer heat to the part. This heating element is sometimes referred to as a halogen lamp heating element due to the halogen cycle. This halogen short or near wave heating technology has several features and related benefits:

heating lamps emit medium to shortwave infrared radiation.

very effective directional heating. Short wave infrared halogen oven and furnace systems are able to selectively heat

specific regions of the part.

specific regions of the part.

match the temperature requirements of the process.

Quartz Halogen & Quartz Tungsten Options:

Lead Styles

Lead Styles

R7s or various lead lengths

R7s or various lead lengths

Quartz Tungsten Elements:

Quartz Tungsten Elements:

QTL – Quartz Tungsten Long Emitter

QTL – Quartz Tungsten Long Emitter

QTM – Quartz Tungsten Medium Emitter

QTM – Quartz Tungsten Medium Emitter

QTS – Quartz Tungsten Short Emitter

QTS – Quartz Tungsten Short Emitter

Pillared Elements:

Pillared Elements:

QHL – Quartz Halogen Long Emitter

QHL – Quartz Halogen Long Emitter

QHM – Quartz Halogen Medium Emitter

QHM – Quartz Halogen Medium Emitter

QHS – Quartz Halogen Short Emitter

QHS – Quartz Halogen Short Emitter